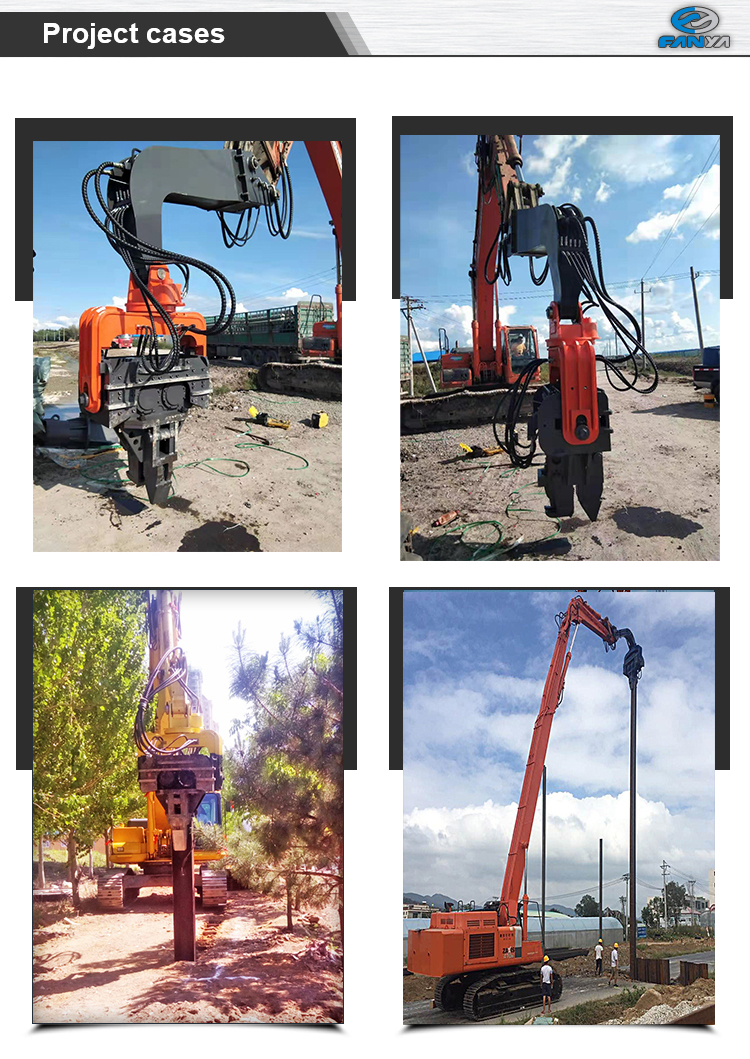

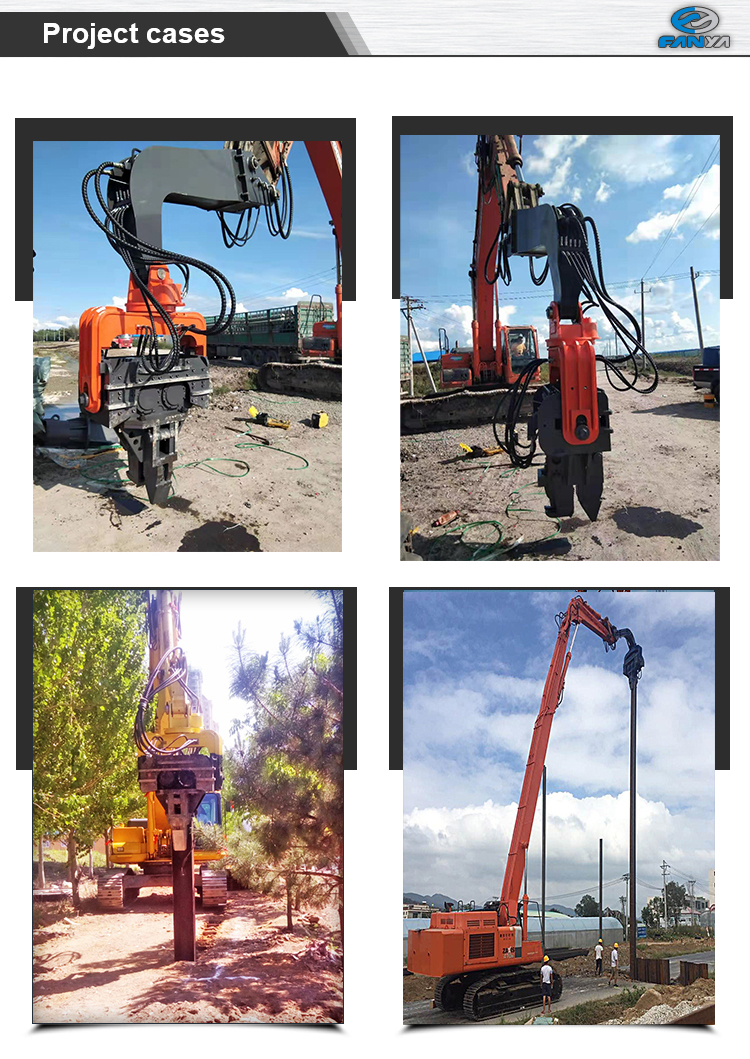

FANYATOP FY series hydraulic mini excavator pile driver is the vibratory driving piling equipment which is use more among a wide variety of foundation projects.

Apart from driving and pulling pilessuch as sheet piles and pipes, excavator vibro hammer are also used for soil densifying or vertical drainage, especially suitable for municipal, bridges, cofferdam, building foundation, etc.

With advanced technology, vibratory pile driver has advantages of low noise, high efficiency, non-pollution and non-damage to piles, etc.

Hydraulic pile driver for mini excavator is using its high frequency vibration to vibrate pile body with high acceleration to pass the vertical vibration of mechanical produce to pile which leading to changes in the soil structure around the pile, strength decrease. Soil around the piles become liquefaction to reduce frictional resistance between side of the pile and the soil. Then using the excavator down force, vibrating pile hammer and pile body weight to sink pile into the soil. When extracting piles, in the condition of vibration to pull out the pile by using excavator lift force. Excitation force needed by pile driving machinery are comprehensive determined by site soil, soil condition, moisture content and type of pile, construction.

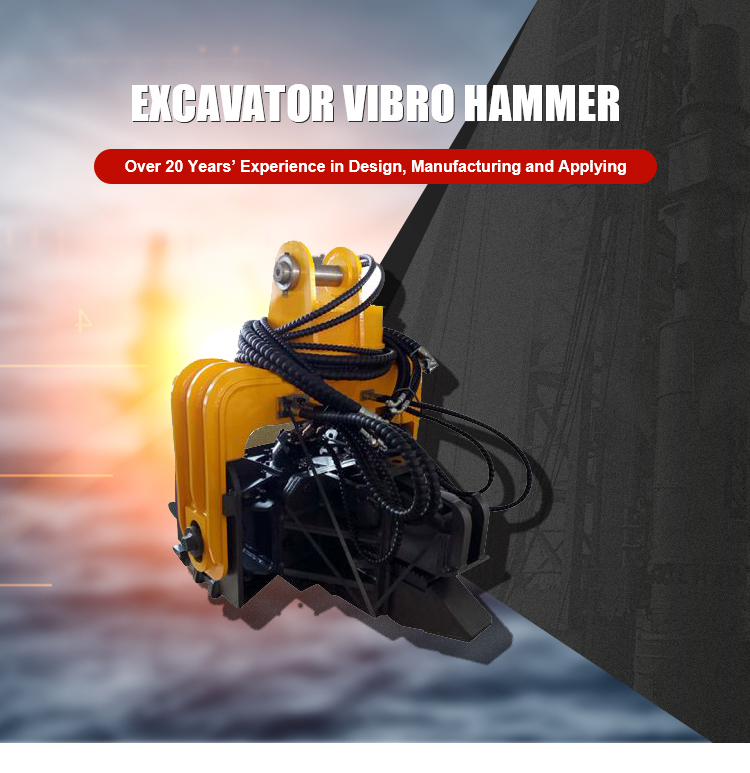

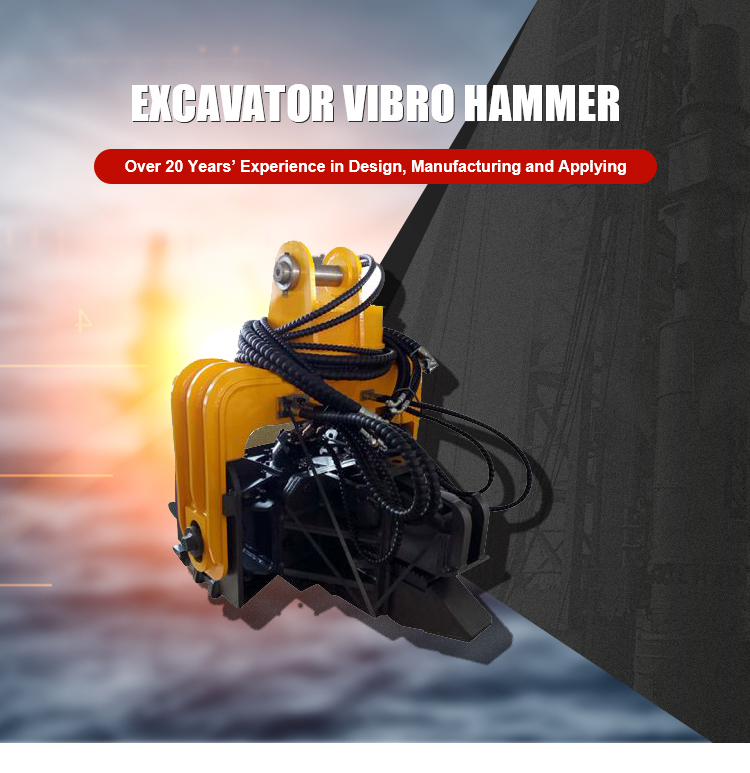

Main feature

1) 360 degree rotation of the middle bracket

2) Various pile driving, sheet pile, pipe pile, H-beam, steel plate, etc.

3) Excellent mobility in narrow places compared with cranes

4) The high shear load of the heavy-duty elastomer cushion prevents vibration from being transmitted to the excavator.

5) Easy installation and control. Suitable for all kinds of workplaces, congested areas, under bridges, narrow roads, minimal noise in urban renewal.

How does a hydraulic excavator pile hammer work?

1. The vibrating pile hammer uses its high-frequency vibration to vibrate the pile body with high acceleration to generate the pile by mechanical vertical vibration, which causes the oil structure around the pile column to change, thereby changing the direction around the pile. Reduces frictional resistance between pile and soil.

2. Then use the excavator to push down, vibrate the pile hammer and the weight of the pile body sink into the pile

When digging a pile, use an excavator hoist to pull the pile out under vibration force.

3. The excitation force required by pile machinery is determined by the soil on the site

Conditions, moisture content and type of pile, construction.

Item | FY300 | FY400 |

Eccentric Moment | 40Nm | 85Nm |

Centrifugal Force | 300kN | 570kN |

Amplitude | 6.8mm | 14mm |

Frequency | 2800rpm | 2800rpm |

Pressure | 240-260kg/cm2 | 240-260kg/cm2 |

Oil Flow | 155-200L/min | 200-255L/min |

Max Turning | 360degree | 360degree |

Package Size | hammer with clamp:1450mm*1550mm*1650mm | hammer with clamp:1650mm*1700mm*1950mm |

vice arm: 3400mm*800mm*1200mm | vice arm: 3400mm*800mm*1400mm |

Total: 7.41cube meters | Total: 8.81cube meters |

Net Weight | hammer with clamp: 2200kg | hammer with clamp: 2800kg |

vice arm: 550kg | vice arm: 780kg |

Total: 2750kg | Total: 3580kg |

Suitable excavator | 20-35tons | 35-50tons |

Packaging & Shipping

The standard set of pile driver excavator include:

- The body of pile driver

- Goose neck (vice arm)

- Clamp;

- Accessories.

We packed with export standard wooden pallet, wooden case or steel case.

Payment Term:

1. T/T,L/C at Sight,,or other payment terms according to actual situations.

2. Trade term: EXW, FOB, CNF, CIF all accepted.

Our Service

1. Suggest suitable model for your project within 24hours when receive your inquiry

2. Delivery time:7-10days after receiving 30%t/t deposit.

3. OEM Service available with CE certificate

4. Warranty:6 months of warranty time for the motor dating from the receipt day. Besides, we will offer life long technical instruction.

5. 24Hours after-sales service via email and phone

6. Enough spare parts in stock.

7. We can offer technical support via phone,email or our engineer come to your jobsite.