Diesel pile hammers are substantial investments for any construction company. To maximize return on this investment and minimize costly repairs, proper diesel pile hammer care and maintenance are essential. By following these guidelines, you can extend the lifespan of your hammer pile equipment and optimize its performance.

Regular Inspections and Cleaning for Optimal Diesel Pile Hammer Care

Consistent inspections are the cornerstone of effective diesel pile hammer maintenance. After each use, dedicate time to cleaning your equipment to remove dirt, debris, and corrosive materials. Focus on the following areas:

Ram and piston: Check for cracks, wear, or damage.

Cylinder: Inspect for scoring or erosion.

Hydraulic system: Monitor fluid levels and look for leaks.

Fuel system: Clean filters and check for fuel contamination.

Cooling system: Ensure proper coolant levels and radiator cleanliness.

Regular cleaning and inspections can help identify potential issues early on, preventing them from escalating into costly repairs.

Lubrication: A Crucial Component of Diesel Pile Hammer Maintenance

Proper lubrication is vital for reducing friction and preventing premature wear on your diesel pile hammer. Adhere to the manufacturer's recommended lubrication schedule and use high-quality lubricants. Pay attention to the following areas:

Moving parts: Apply grease or oil to all moving components, including pins, bushings, and bearings.

Hydraulic system: Use the recommended hydraulic fluid and change it according to the manufacturer's guidelines.

Fuel system: Use high-quality diesel fuel with appropriate additives to prevent injector clogging.

By maintaining a consistent lubrication routine, you can significantly improve the performance and lifespan of your diesel pile hammer.

Preventative Maintenance: Protecting Your Investment

Preventative maintenance is key to extending the life of your diesel pile hammer. Schedule regular maintenance checks and address any issues promptly. Essential maintenance tasks include:

Engine service: Follow the manufacturer's recommended service intervals for oil changes, filter replacements, and tune-ups.

Hydraulic system service: Check for leaks, replace worn hoses, and flush the system as needed.

Undercarriage inspection: Inspect tracks or tires for wear and damage.

Safety inspections: Verify the functionality of safety devices, such as emergency stops and alarms.

By investing in preventative maintenance, you can avoid unexpected breakdowns and costly repairs, ultimately saving you money on diesel pile hammer price in the long run.

The Importance of Operator Training

Well-trained operators are crucial for the proper care and operation of diesel pile hammers. Investing in operator training can significantly extend the life of your equipment. Key training areas include:

Equipment operation: Familiarize operators with the controls, functions, and safety features of the diesel pile hammer.

Maintenance procedures: Teach operators how to perform basic inspections and maintenance tasks.

Troubleshooting: Provide guidance on identifying and addressing common issues.

Safety protocols: Emphasize the importance of following safety guidelines and using personal protective equipment.

Proper operator training can help prevent operator error, which can lead to costly repairs and downtime.

Conclusion

By implementing a comprehensive diesel pile hammer care and maintenance program, you can significantly extend the life of your equipment, reduce downtime, and optimize its performance. Regular inspections, proper lubrication, preventative maintenance, and operator training are essential components of a successful care program.

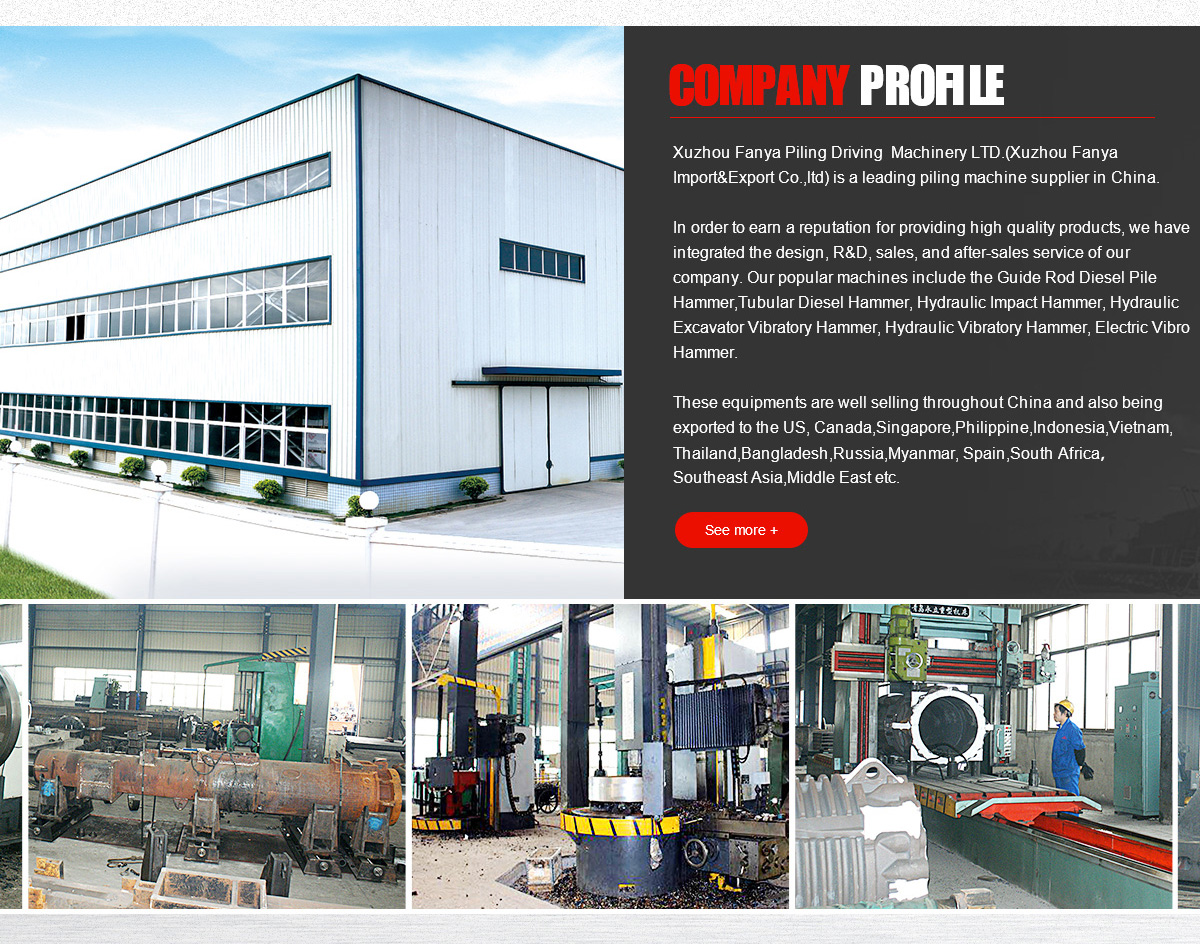

Remember, investing time and resources into maintaining your diesel pile hammer will pay dividends in the long run. If you require expert maintenance services or replacement parts, contact FANYATOP, a leading provider of diesel pile hammers.