Understanding Hydraulic Impact Hammers

Hydraulic impact hammers play a crucial role in construction and infrastructure projects, known for their efficiency in driving piles into various types of soil and substrates. As a core tool in foundation work, hydraulic impact hammers provide unmatched power and precision. The wide range of Hydraulic Impact Hammers Applications makes them indispensable in building bridges, ports, and other large structures where strong foundations are critical. The hydraulic mechanism provides a more controlled force compared to traditional pile-driving methods, reducing the risk of damaging the surrounding environment or piles.

Basic Functionality

The basic functionality of a hydraulic impact pile hammer is straightforward yet powerful. These hammers use hydraulic pressure to generate a strong downward force that drives piles deep into the ground. The energy delivered is adjustable, making it versatile for different projects, from soft soils to hard rock substrates. Hydraulic impact hammers offer superior control, ensuring precision in pile placement, which is vital for the structural integrity of buildings and other infrastructure projects.

How Hydraulic Impact Hammers Work

The core mechanics behind hydraulic impact hammers involve a hydraulic cylinder filled with pressurized fluid. When activated, the fluid drives a piston, which, in turn, forces a hammering blow onto the pile. The repeated action allows the hammer to drive the pile deeper into the ground with every stroke. Unlike traditional impact hammers, hydraulic hammers provide consistent power output, making them more effective for modern construction needs. Whether working on land or offshore, these hammers adapt easily to different environments, making them a versatile choice for contractors.

Types of Hydraulic Impact Hammers

There are various Hydraulic impact hammer types, each designed for specific applications in the construction industry. Some hammers are ideal for driving large steel piles, while others are better suited for smaller, more delicate structures. Choosing the right hydraulic impact hammer is essential for maximizing efficiency and ensuring project success. Contractors must consider factors like the type of pile, the site’s soil conditions, and the power required to drive the pile to the desired depth.

Differentiating Between Various Models

When selecting a hydraulic impact hammer, it's important to understand the differences between the available models. Some hammers are designed for use with heavy piles, requiring significant power and durability, while others are better suited for lighter, more flexible projects. Some models prioritize efficiency and speed, ideal for large-scale projects where time is of the essence. Differentiating between these models based on their Hydraulic Impact Hammers Applications ensures that contractors select the right tool for the job.

Specific Uses for Each Type

Each hydraulic impact hammer type serves a particular purpose, depending on the construction project's needs. Heavy-duty models are commonly used for large-scale infrastructure projects like bridges and ports, where deep foundations are essential. On the other hand, smaller hydraulic impact hammers may be used in urban construction for high-rise buildings and other confined areas, where precision and control are vital. Understanding the specific uses of each hammer type helps contractors optimize their operations, ensuring efficient and safe pile driving for a wide variety of projects.

Conclusion

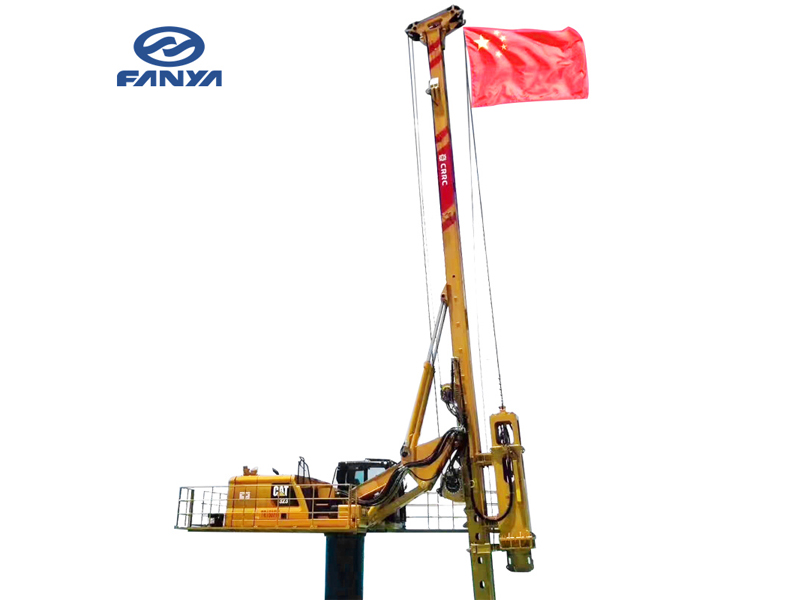

Hydraulic impact hammers are an essential tool for modern construction, providing precise and powerful pile driving solutions for various applications. With the right hydraulic impact pile hammer, contractors can complete projects efficiently, even in challenging environments. FANYATOP offers a range of hydraulic impact hammers tailored to meet your specific project needs, whether you're working on large-scale infrastructure or smaller urban developments. Choosing FANYATOP guarantees high-quality equipment, reliable customer service, and expert support to ensure your projects run smoothly from start to finish.

FAQs

1. What is the difference between a hydraulic impact hammer and a hydraulic breaker?

While both use hydraulic power, hydraulic impact hammers are primarily used for pile driving, while hydraulic breakers are designed for breaking concrete or rock.

2. Can hydraulic impact hammers be used for underwater pile driving?

Yes, there are specialized hydraulic impact hammers designed for underwater applications. These hammers typically have additional features to withstand the pressure and corrosive environment of underwater work.

3. How do I maintain a hydraulic impact hammer?

Checking and replacing hydraulic oil as needed.

Inspecting and maintaining the hydraulic hoses and fittings.

Cleaning and lubricating moving parts.

Following the manufacturer's recommended maintenance schedule.

Regular maintenance is essential for ensuring the optimal performance and longevity of a hydraulic impact hammer. This includes: