Hydraulic impact hammers serve as essential tools in construction and demolition. These machines utilize hydraulic fluid to generate significant force. Construction professionals rely on these hammers to break through tough materials like concrete and rock. The efficiency of hydraulic impact hammers enhances productivity on job sites. Understanding how does a hydraulic impact hammer work provides insight into their effectiveness. The general purpose involves driving piles and breaking materials efficiently. Hydraulic impact hammers contribute significantly to modern engineering projects.

How Does a Hydraulic Impact Hammer Work

Role of Hydraulic Fluid

Hydraulic fluid plays a crucial role in energy transfer within hydraulic impact hammers. The fluid moves under high pressure, creating the force needed for operation. This energy transfer ensures efficient performance. Hydraulic fluid also maintains the hammer's temperature and reduces wear.

The importance of hydraulic fluid in hammer operation cannot be overstated. The fluid enables smooth movement of components. Consistent pressure from the fluid ensures reliable impact generation. Proper maintenance of hydraulic fluid enhances the hammer's lifespan.

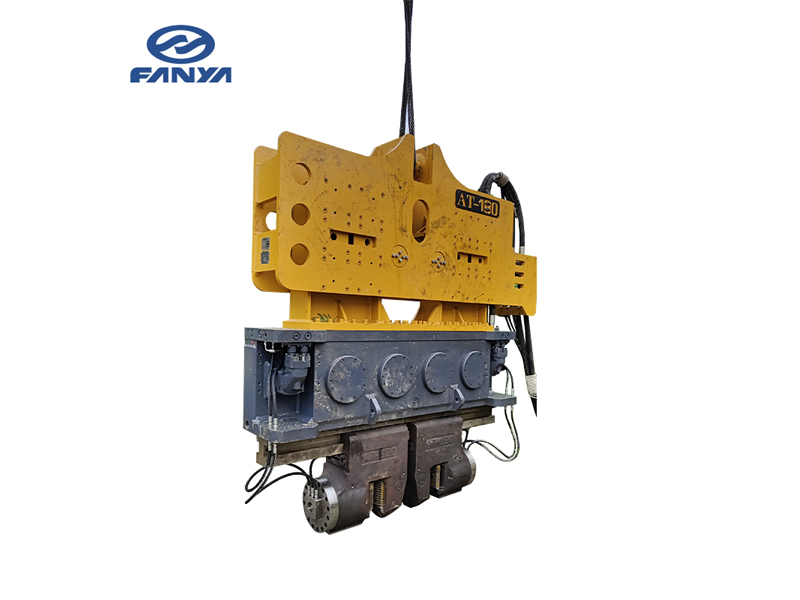

Components: Piston and Chisel

The piston serves as a key component in generating force. The piston moves rapidly within the cylinder. This movement creates the impact force necessary for breaking materials. The piston’s efficiency directly affects the hammer's performance.

The chisel functions as the primary tool for material impact. The chisel transfers the force generated by the piston to the target material. This action breaks or drives through tough surfaces. The chisel's design and material determine its effectiveness in various applications.

Mechanics of Hydraulic Impact Hammers

Pressure Build-up Process

The hydraulic system operation in impact hammers involves a series of precise actions. Hydraulic fluid flows through the system at high pressure. This movement creates the necessary force for the hammer's function. The energy transfer process is crucial for understanding how does a hydraulic impact hammer work. The hydraulic system must maintain consistent pressure levels to ensure efficient performance.

The pressure release mechanism plays a vital role in the hammer's operation. Pressure builds up in the upper chamber during the upward stroke. The main valve releases this pressure, allowing the piston to move. This release generates the impact force required for breaking materials. The pressure release mechanism ensures the hammer operates smoothly and effectively.

Impact Generation

The conversion of hydraulic energy to mechanical force is a key aspect of how does a hydraulic impact hammer work. The piston moves rapidly within the cylinder, driven by hydraulic pressure. This movement converts hydraulic energy into mechanical force. The generated force impacts the chisel, which then breaks or drives through materials. The conversion process is essential for the hammer's effectiveness in various applications.

The impact cycle and frequency determine the hammer's performance. Each cycle involves the piston striking the chisel with force. The frequency of these cycles affects the hammer's efficiency. A higher frequency results in more impacts per minute, increasing productivity. Understanding how does a hydraulic impact hammer work involves recognizing the importance of impact cycle and frequency. These factors contribute to the hammer's adaptability and effectiveness in different tasks.

Adaptability of Hydraulic Impact Hammers

Suitability for Different Materials

Hard vs. Soft Materials

Hydraulic impact hammers demonstrate remarkable adaptability across various materials. Hard materials like concrete and rock require significant force. Hydraulic impact hammers deliver this force efficiently. Soft materials such as asphalt need a gentler approach. The hammer's versatility ensures effective performance in both scenarios.

Adjustments for Material Type

Operators can adjust hydraulic impact hammers to suit different material types. Pressure settings play a crucial role in this adaptability. Higher pressure suits hard materials, while lower pressure fits softer ones. These adjustments optimize the hammer's performance and efficiency.

Applications in Various Industries

Construction

The construction industry relies heavily on hydraulic impact hammers. These tools break through concrete and drive piles with precision. Construction projects benefit from the speed and power of these hammers. Efficiency and reliability make them indispensable on job sites.

Demolition

Demolition tasks demand robust equipment. Hydraulic impact hammers excel in dismantling structures. The force generated by the hammer ensures quick and effective demolition. This capability enhances safety and productivity in demolition projects.

Mining

Mining operations require powerful tools for material extraction. Hydraulic impact hammers provide the necessary force for breaking rocks. These hammers improve efficiency in mining activities. The adaptability of the hammer makes it suitable for various mining environments.

Key Features and Benefits

Efficiency and Power

Energy Consumption

Hydraulic impact hammers optimize energy use. The design ensures minimal waste during operation. Efficient energy consumption leads to cost savings. Construction sites benefit from reduced fuel expenses.

Output Force

The output force of hydraulic impact hammers remains impressive. High-pressure hydraulic systems generate substantial power. This force breaks through tough materials with ease. Consistent output enhances productivity on job sites.

Durability and Maintenance

Longevity of Components

Hydraulic impact hammers feature durable components. Manufacturers use high-quality materials in construction. Robust design extends the lifespan of the equipment. Long-lasting tools reduce replacement costs for operators.

Maintenance Practices

Regular maintenance ensures optimal performance. Operators should follow recommended service schedules. Proper lubrication reduces wear on moving parts. Routine checks prevent unexpected breakdowns.

Hydraulic impact hammer for pile driver play a crucial role in construction, demolition, and mining. The understanding of hydraulic fluid dynamics and component functions enhances operational efficiency. Mastery of these tools leads to improved productivity and safety on job sites.