Master Rotary Drilling Machine: Your Ultimate Guide

The rotary drilling machine has become an indispensable tool in various industries, from construction and mining to exploration and environmental assessment. Its ability to efficiently create precise boreholes makes it a preferred choice for professionals seeking accurate and productive drilling operations. This comprehensive guide will delve into the intricacies of rotary drilling machines, exploring their components, working principles, applications, and factors to consider when making a purchase.

Understanding Rotary Drilling Machines

A rotary drilling machine is a specialized piece of equipment designed to create boreholes by rotating a drill bit into the ground. It consists of several key components, including a power source, drilling mechanism, and support structure. The power source, typically a diesel or electric motor, drives the drilling process, while the drilling mechanism comprises the drill bit, drill rods, and swivel assembly. The support structure provides stability and maneuverability to the machine.

How Does a Rotary Drilling Machine Work?

The operation of a rotary drilling machine involves a series of interconnected processes. The power source generates rotational force, which is transmitted through the drill rods to the drill bit. As the drill bit rotates, it cuts through the soil or rock, creating a borehole. The extracted material, or cuttings, is removed from the hole through a circulation system that involves drilling fluid. This fluid cools and lubricates the drill bit, while also transporting cuttings to the surface.

Types of Rotary Drilling Machines

Rotary drilling machines come in various types, each suited to specific applications and geological conditions. The primary classifications include:

Surface Drilling Rigs: These rigs are mounted on a stationary base and are typically used for shallow to moderate-depth drilling.

Crawler-Mounted Drilling Rigs: Equipped with tracks, these rigs offer better mobility and are suitable for rough terrain.

Truck-Mounted Drilling Rigs: Mounted on a truck chassis, these rigs provide excellent mobility and can be easily transported to different locations.

Down-the-Hole (DTH) Drilling Rigs: These rigs use a compressed air-powered drill bit for drilling in hard rock formations.

Factors to Consider When Purchasing a Rotary Drilling Machine

Selecting the right rotary drilling machine is crucial for project success. Several factors should be considered:

Project Requirements: Define the drilling depth, hole diameter, and geological conditions to determine the necessary machine specifications.

Mobility Needs: Assess the terrain and accessibility of the drilling site to determine the required rig type.

Power Source: Choose between diesel, electric, or hydraulic power based on environmental considerations, fuel availability, and operational costs.

Budget: Establish a clear budget for the purchase or rental of the rotary drilling machine, including operating and maintenance costs.

Safety Features: Prioritize safety by selecting a machine equipped with essential safety features and emergency shutdown systems.

FAQs About Rotary Drilling Machines

Q: What is the difference between rotary drilling and percussion drilling?

A: Rotary drilling uses a rotating drill bit to cut through the material, while percussion drilling relies on repeated impacts to break the material.

Q: What factors affect drilling speed?

A: Drilling speed is influenced by factors such as drill bit type, rotational speed, feed rate, and soil or rock conditions.

Q: How often should I maintain my rotary drilling machine?

A: Regular maintenance is recommended, typically after a certain number of operating hours or at specified intervals. Refer to the manufacturer's guidelines for specific recommendations.

Q: What safety precautions should be taken when operating a rotary drilling machine?

A: Always wear appropriate personal protective equipment, follow operating instructions, and adhere to site safety guidelines. Regular inspections of the machine and its components are essential.

Q: Can rotary drilling machines be used in underwater applications?

A: Yes, specialized rotary drilling rigs are available for underwater operations, such as offshore drilling and subsea exploration.

By carefully considering these factors and following best practices, you can select and operate a rotary drilling machine effectively, ensuring the success of your drilling projects.

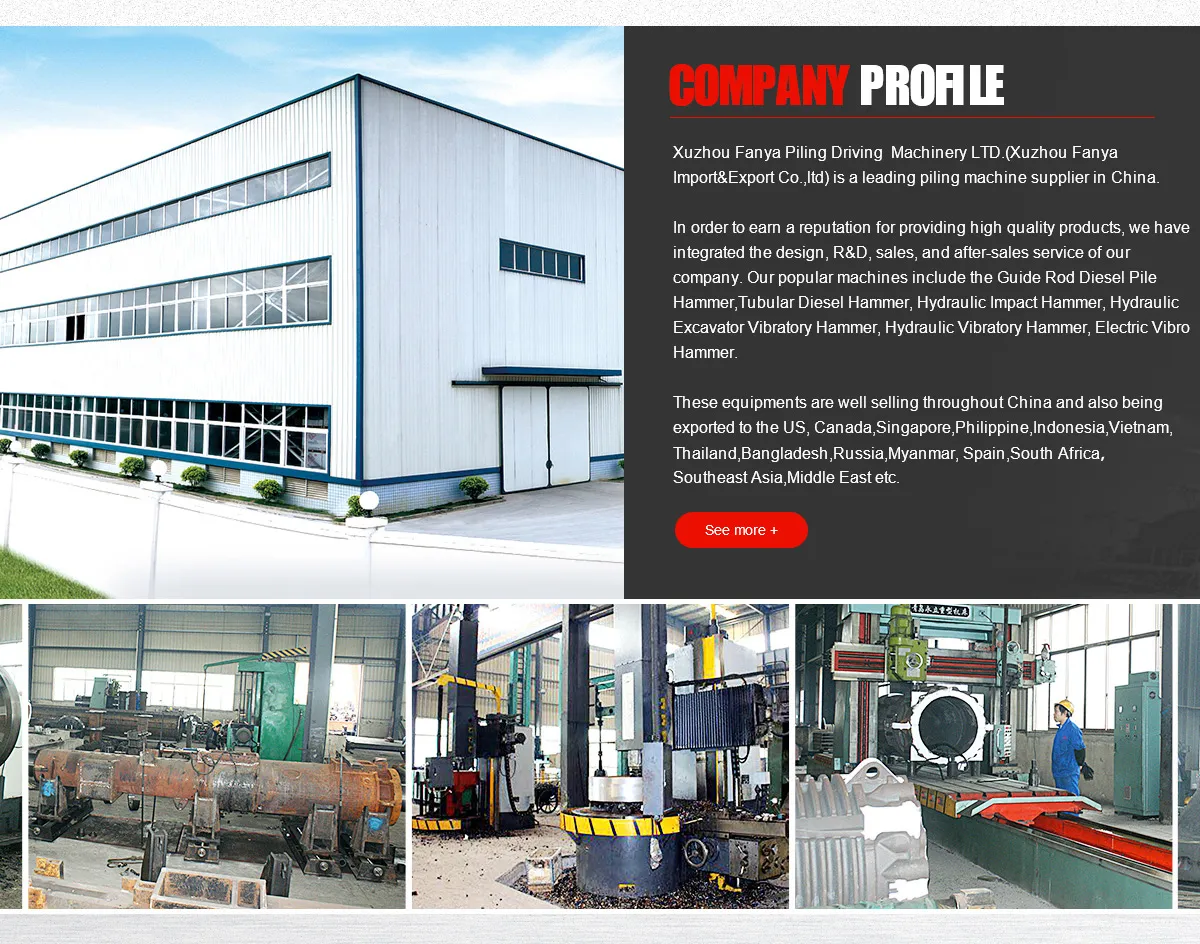

FANYA: Your Trusted Rotary Drilling Machine Manufacturer

When searching for a reliable and efficient rotary drilling machine for sale, look no further than FANYA. As a leading rotary drilling machine factory, we offer a wide range of high-quality machines to suit various applications. Our commitment to innovation and customer satisfaction has made us a trusted partner for businesses worldwide.