FANYATOP brand FHP series hydraulic piling impact hammer have various models (3T, 5T, 7T, 9T, 11T, 12T, 14T, 16T). Combined pile caps can be used. The applicable pile caps can be replaced according to the shape and specifications of the piles.

Hydraulic impact hammers belong to impact pile hammers, which can be divided into single acting and double acting types according to their structure and working principle. The so-called single acting type refers to the rapid release of hydraulic impact pile driving hammer core after it is lifted to a predetermined height by a hydraulic device, and the impact hammer core strikes the pile body in a free fall manner; Double acting refers to the process where the hydraulic impact hammer pile driver core is lifted to a predetermined height by a hydraulic device, and acceleration energy is obtained from the hydraulic system to increase the impact velocity and strike the pile. This also corresponds to two pile driving theories. The single acting hydraulic impact pile hammer corresponds to the heavy hammer light striking theory, characterized by a larger hammer core weight, lower impact velocity, and longer hammering time. The pile hammer has a large penetration per strike, suitable for various shapes and materials of piles, with a low pile damage rate, especially suitable for driving concrete pipe piles. The double acting impact hammer pile driving corresponds to the theory of light hammer and heavy hammer, characterized by a smaller hammer core weight, higher impact velocity, and shorter hammer pile action time. It has a large impact energy and is most suitable for driving steel piles.

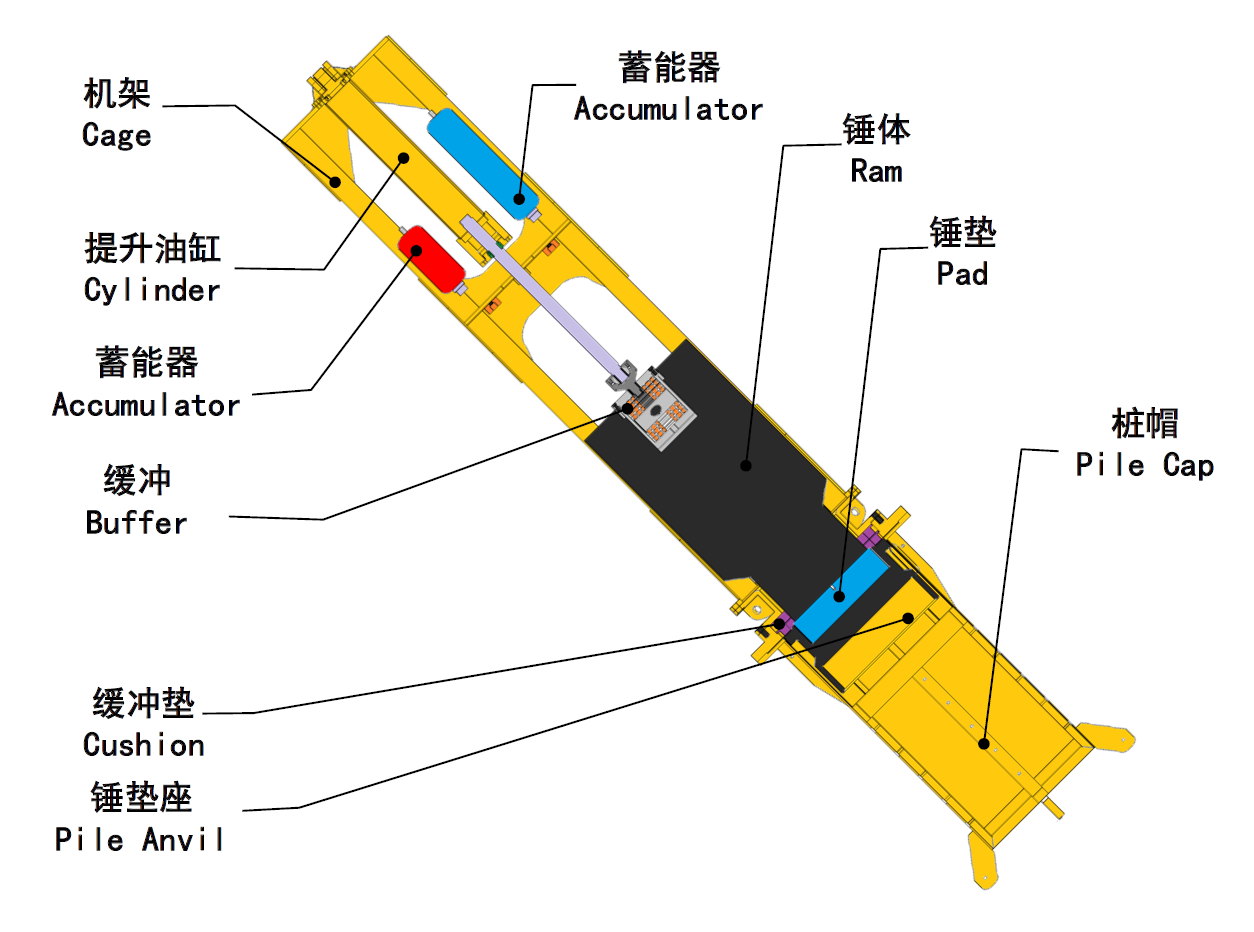

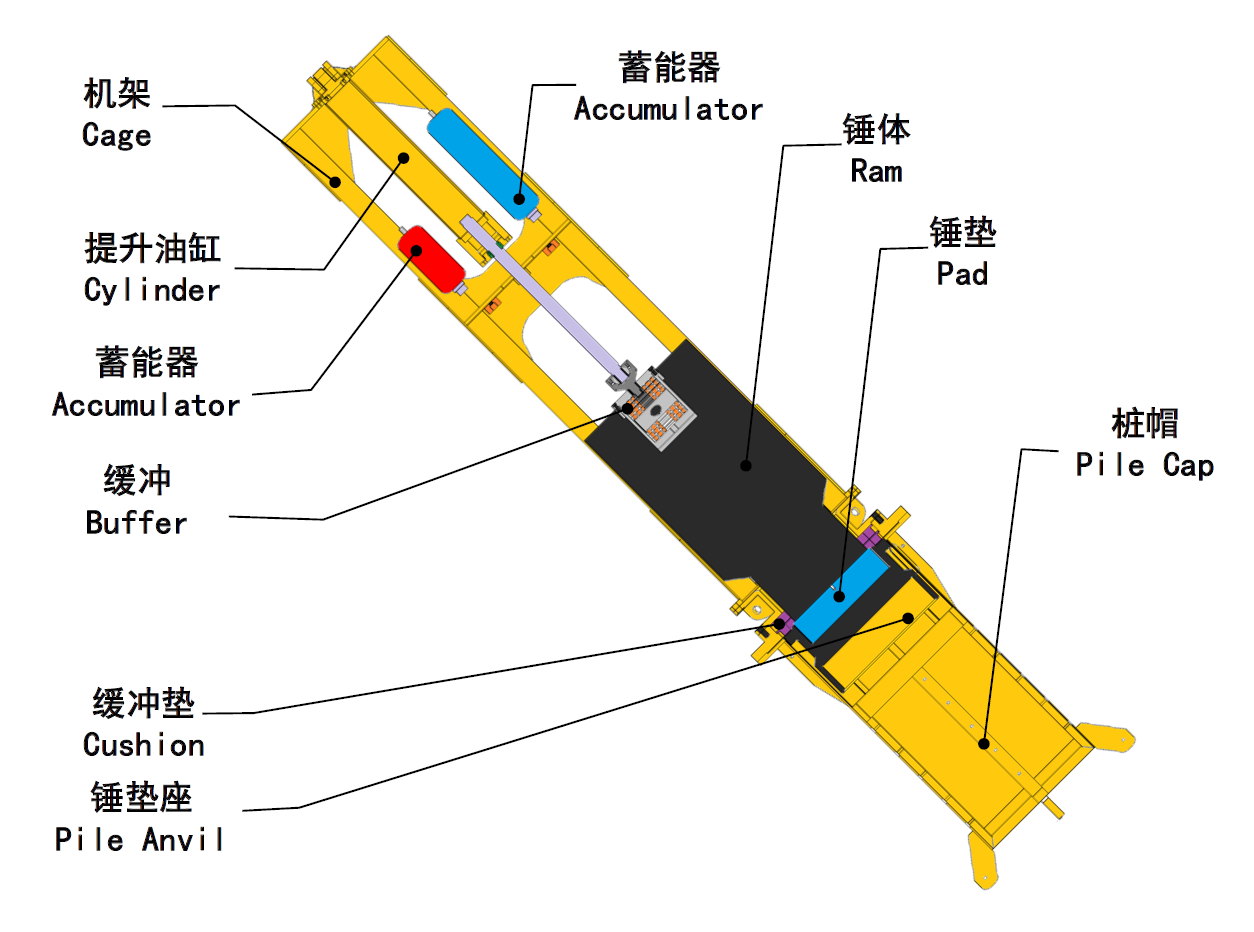

Main parts of

1. Cylinder

2. Accumulator

It functions high and low pressure . it reduces the shock pressure ,and control the ram to drop in a speed 130% of free acceleration.

3. Piston rod

4. Ram stroke range

Operator can see ram drop height easily and can adjust ram stroke height during pile driving through remote control box

5. Ram

It is comprised of one or more ram segments and stands complicated physical and chemical tests before application

6. Drive cap

All the cushions are inserted in it. They could protect the hammer structure , components and piles ,reducing the noisy.

7. Power pack

Piling Hammer Type | FHP3 | FHP5 | FHP7 | FHP9 | FHP11 | FHP12 | FHP14 | FHP16 |

Ram Mass | kg | 3000 | 5000 | 7000 | 9000 | 11000 | 12000 | 14000 | 16000 |

Stroke (Range) | mm | 0-1200 | 0-1500 | 0~1200 | 0~1500 |

Max.Impact Energy | kj | 36 | 75 | 84 | 108 | 132 | 180 | 210 | 240 |

Frequency (Range) | min-1 | 40-120 | 36 |

Flow Requred | L/min | ≧120 | ≧180 | ≧180 | ≧180 | ≧180 | 450 | 450 | 450 |

Working Pressure | Bar | 160 | 220 | 250 | 280 | 310 | 180 | 250 | 280 |

Overall Size ( LxWxH ) | mm | 3650x1520 x1080 | 5250x990 x1500 | 6317x766 x775 | 6317x766 x775 | 6887x766 x775 | 5940x1570 x1830 | 6210x1570 x1830 | 6480x1570 x1830 |

Overall Weight | kg | 6200 | 8300 | 10200 | 12200 | 14200 | 19600 | 21800 | 24000 |

Power Pack Type | HP180 | HP360 |

Engine | Type | 6BTA5.9-C 180 | NTA855-P360 |

Power | KW/HP | 132/180 | 269/360 |

Rated Speed | rpm | 2200 | 2100 |

Max.Presusure | Bar | 350 | 180 | 250 | 280 |

Max.Flow | L/min | 280 | 450 |

Overall Size ( LxWxH ) | mm | 2580X1332X1818 | 3800X1500X2400 |

Overall Weight ( Without Oil fuel ) | kg | 2000 | 4500 |

Business Support

1. Suggest the best solution(suitable model) after study clients’ project and pile information(geological report,pile type,pile lenth,pile size,match with what machinery....)

2. Provide drawings for clients to confirm within three days after signing the contract for non-standard products, and produce according to the drawings(pile leader and pile cap)

3. Every hydraulic impact hammer will be tested well before shippment and operation Instruction will be sent via courier

4. Timely parts service:enough parts stock

5. Our engineers can come to client jobsite for technical support . 24 hours After-sale service hotline 0516-86225766