Detail Description Of diesel pile driving hammer

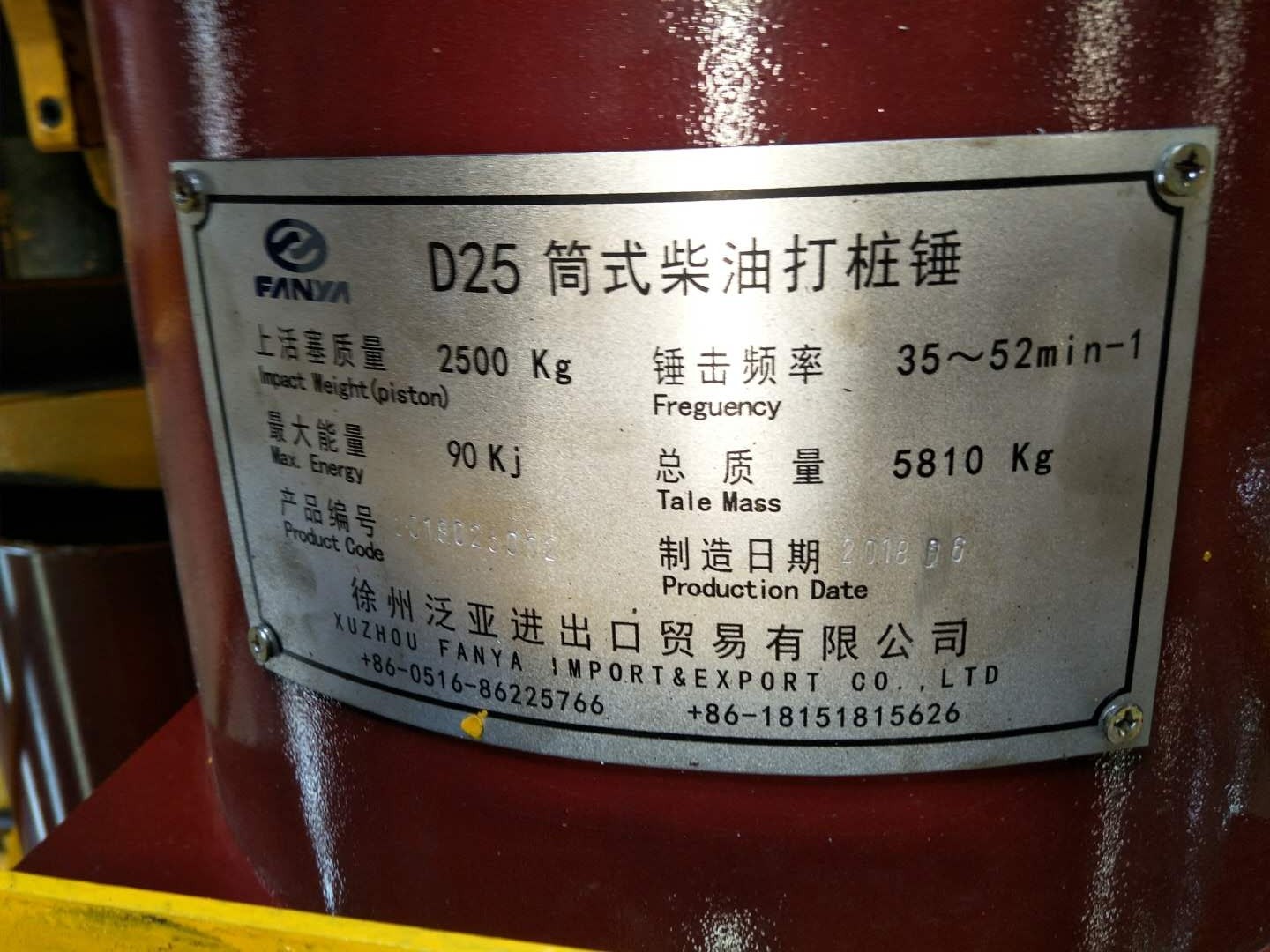

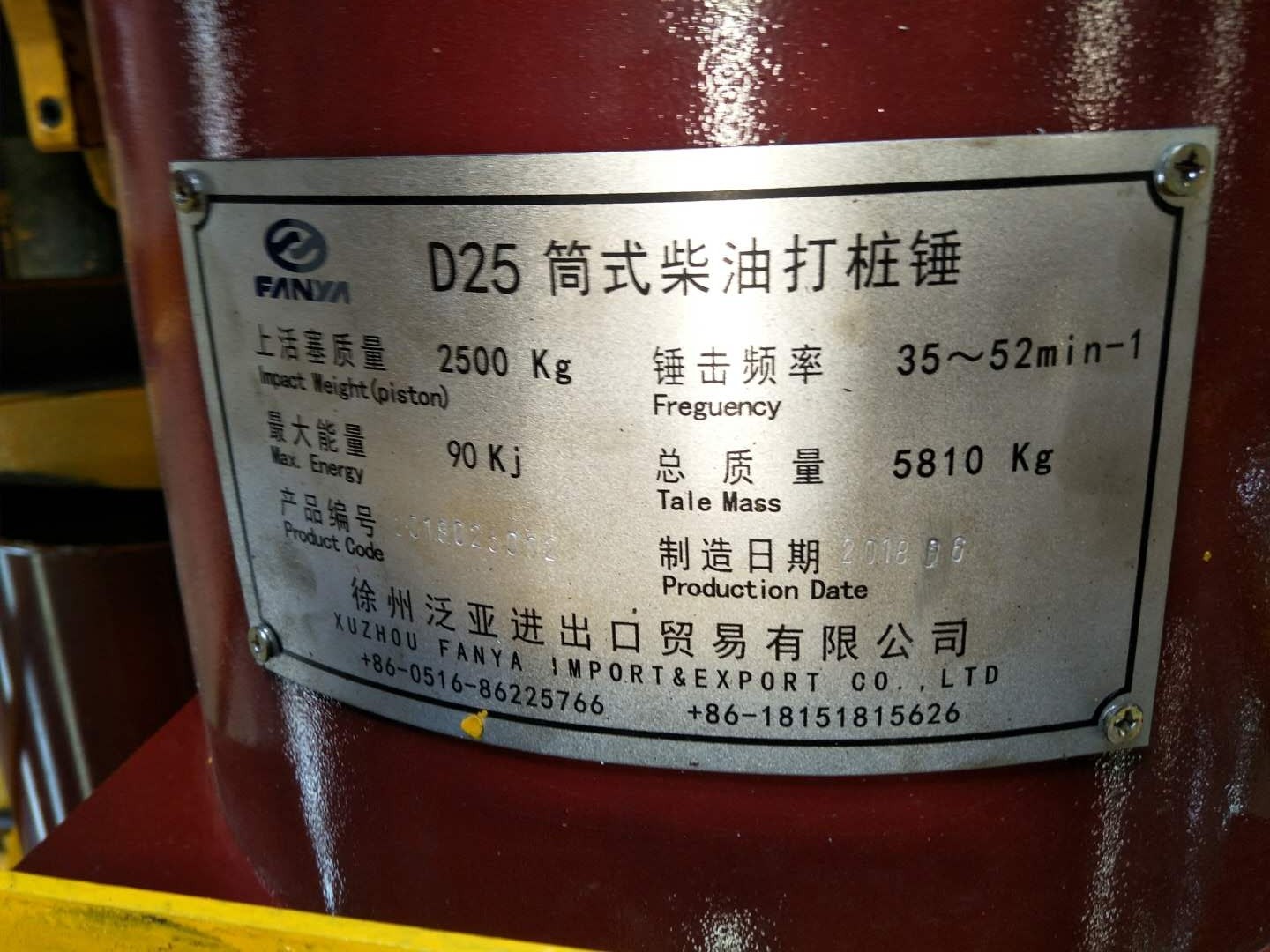

FANYATOP brand D series diesel hammers are over 20 Years’ Experience in Design, Manufacturing and Applying,developed full series cylinder type diesel pile hammers.popular models :D19, D25,D30,D36,D46,D62,D80,D100,D128,D138..D180

2. Fuel supply system

Composed of fuel tank 5, filter 6, fuel delivery pipe 7, and fuel pump 8. There are two types of fuel pumps for cylindrical diesel hammers: low-pressure plunger type and high-pressure nozzle type.

The fuel supply can be adjusted by adjusting the lever.

3. Cooling system

The cylindrical diesel hammer releases a large amount of heat energy during operation, causing the temperature of components such as the cylinder and piston to rise. Therefore, it will reduce the viscosity of the lubricating oil, intensify the wear of components, and easily cause premature ignition, which will prevent the pile hammer from working properly. The commonly used cooling systems include water-cooled and air-cooled. The cylindrical diesel hammers produced by German company Delmag are all air-cooled, and small pile hammers are also commonly air-cooled. The cooling method is to install heat sinks outside the water tank. Air cooling structure is simpler and more convenient to use than water cooling, but the cooling effect is better than air cooling.

4. Landing gear

The landing gear of the cylindrical diesel hammer has two main functions: one is to lift the upper piston for starting, and the other is to lift the entire pile hammer.

Packaging & Shipping

The standard set of pile hammer include:

- diesel pile hammer

- drive cap

- Accessories.

We packed with export standard steel carrier and ship by 20GP or 40GP container

Payment Term:

1. T/T,L/C at Sight,,or other payment terms according to actual situations.

2. Trade term: EXW, FOB, CNF, CIF all accepted.

Business Support

1. Suggest the best solution(suitable model) after study clients’ project and pile information(geological report,pile type,pile lenth,pile size,match with what machinery....)

2. Provide drawings for clients to confirm within three days after signing the contract for non-standard products, and produce according to the drawings(pile leader and pile cap)

3. Every diesel pile hammer will be tested well before shippment. Every single product has its own production code, certification of quality and operation Instruction

4. Timely parts service:enough parts stock

5. Our engineers can come to client jobsite for technical support .24 hours After-sale service hotline 0516-86225766