Detail Description Of D36 Cylinder single acting diesel impact hammers

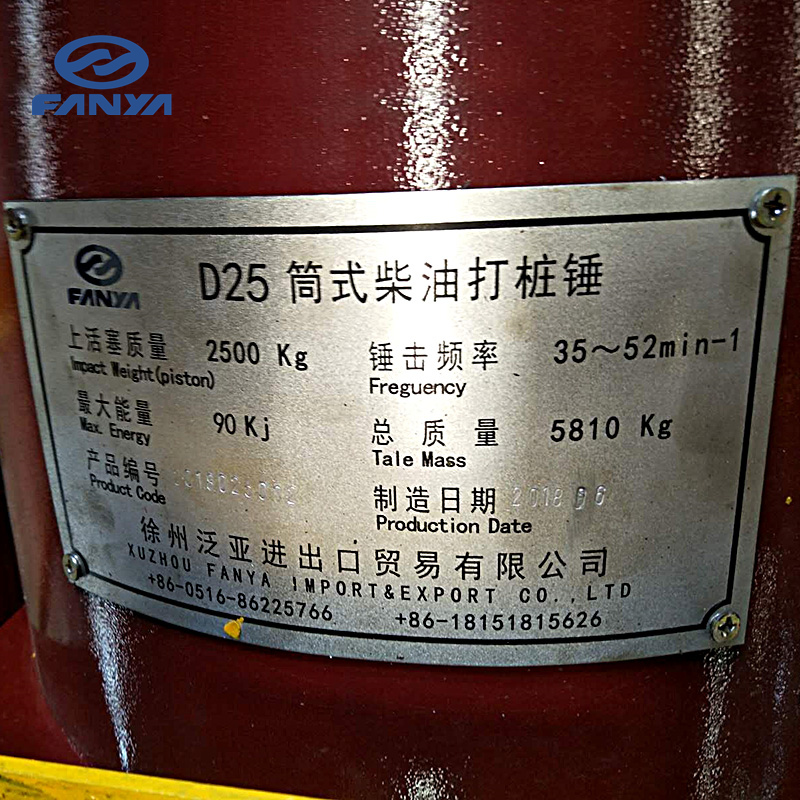

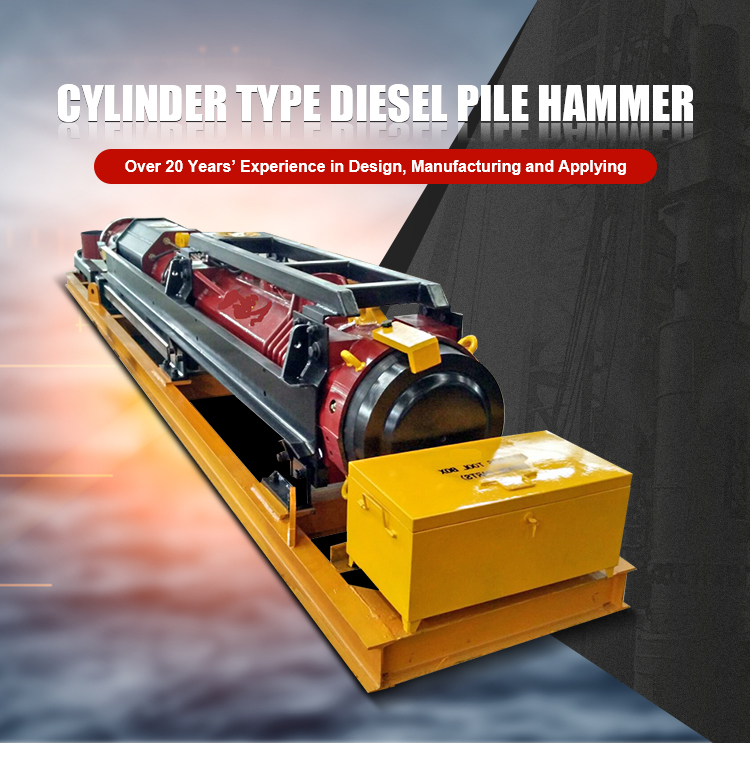

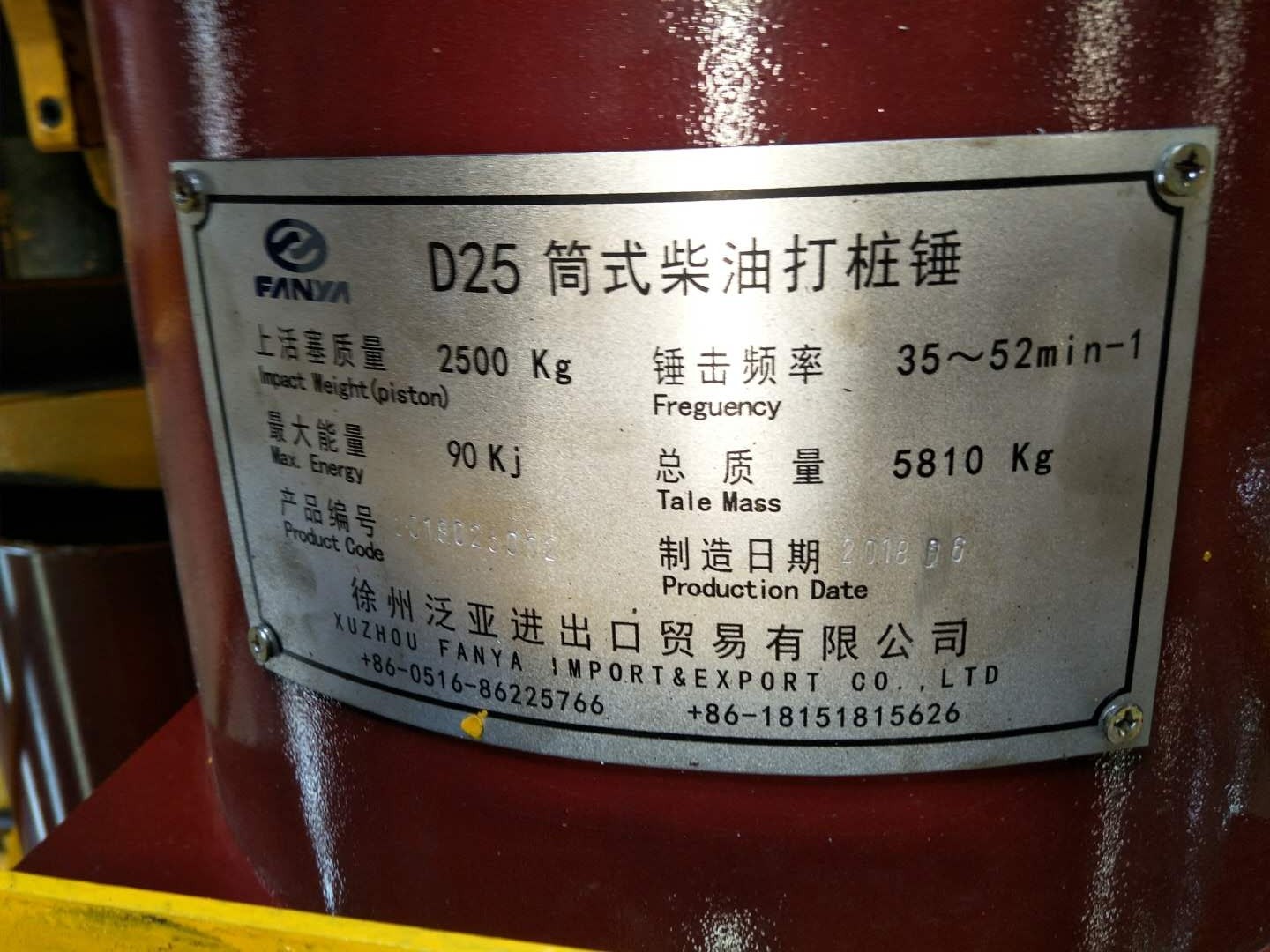

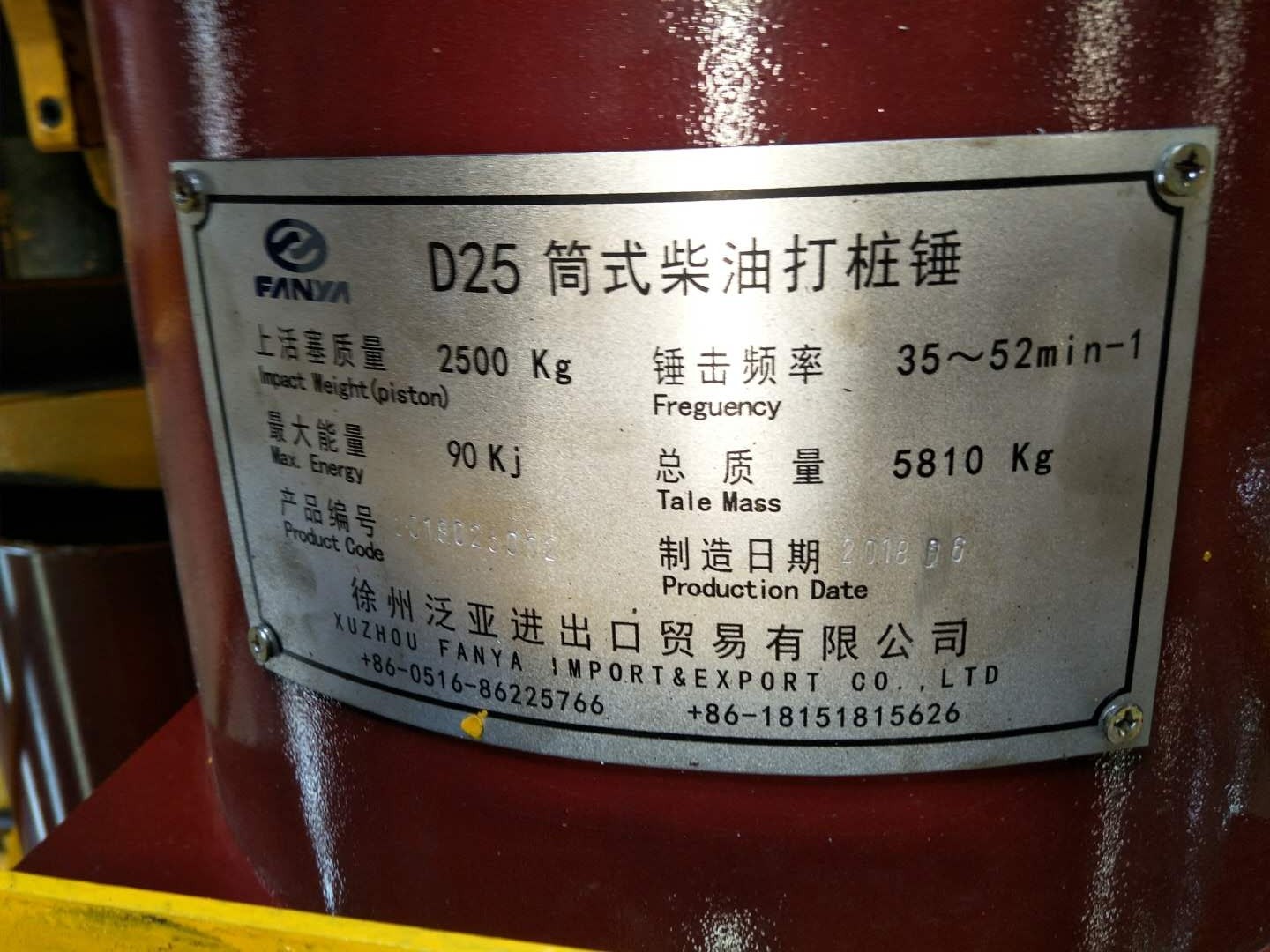

FANYATOP brand D series diesel hammers are over 20 Years’ Experience in Design, Manufacturing and Applying,developed full series cylinder type diesel pile hammers.popular models :D19, D25,D30,D36,D46,D62,D80,D100,D128,D138..D180

Construction of cylinder diesel hammer

It mainly consists of a hammer body, a fuel supply system, a cooling system, and a starting system.

1. Hammer body

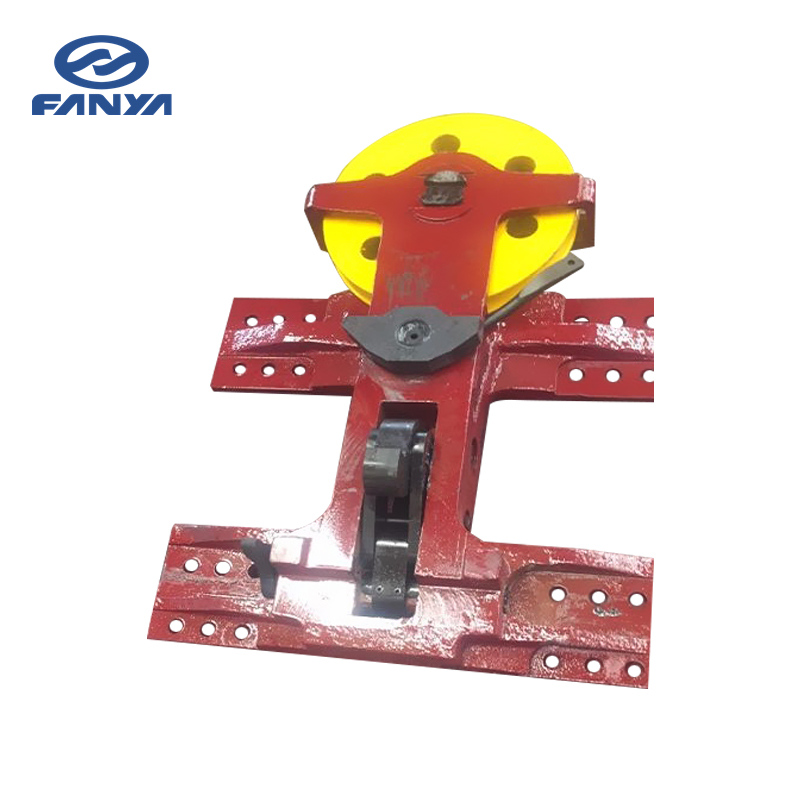

It is mainly composed of guide cylinder 1, upper cylinder 2, lower cylinder 9, upper piston 4, lower piston 11, and buffer rubber pad 17. The guiding cylinder guides the direction of the upper piston when driving the inclined pile, and can also prevent the upper piston from jumping out of the hammer body. The upper cylinder is located between the guiding cylinder and the lower cylinder, serving as the guiding device for the upper piston. The lower cylinder is the working cylinder. Both the upper and lower pistons are working pistons that withstand significant impact forces. During the pile driving process, the upper piston is prone to breakage. The buffer pad is installed at the connection between the piston and the lower cylinder, and its function is to reduce the impact of the upper piston on the cylinder. Inertial lubrication is used between the upper cylinder and the upper piston, while forced lubrication is used between the lower piston and the lower cylinder. The lubricating oil is pressurized by the lubricating oil pump, which is operated by the movement of the lower cylinder.

Packaging & Shipping

The standard set of pile hammer include:

- diesel pile hammer

- drive cap

- Accessories.

We packed with export standard steel carrier and ship by 20GP or 40GP container

Payment Term:

1. T/T,L/C at Sight,,or other payment terms according to actual situations.

2. Trade term: EXW, FOB, CNF, CIF all accepted.

Business Support

1. Suggest the best solution(suitable model) after study clients’ project and pile information(geological report,pile type,pile lenth,pile size,match with what machinery....)

2. Provide drawings for clients to confirm within three days after signing the contract for non-standard products, and produce according to the drawings(pile leader and pile cap)

3. Every diesel pile hammer will be tested well before shippment. Every single product has its own production code, certification of quality and operation Instruction

4. Timely parts service:enough parts stock

5. Our engineers can come to client jobsite for technical support .24 hours After-sale service hotline 0516-86225766