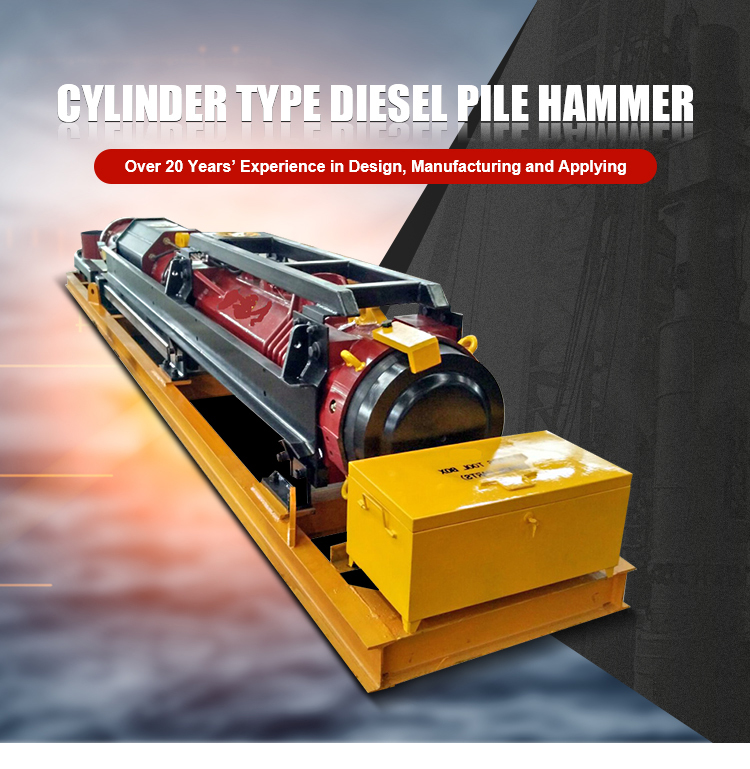

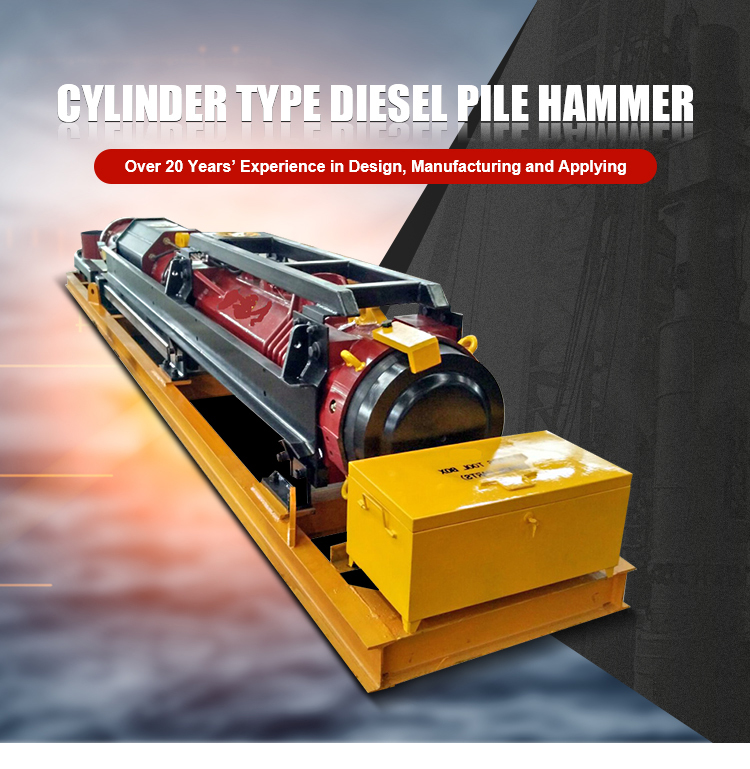

FANYATOP brand D Series diesel hammer pile driver machine are over 20 Years’ Experience in Design, Manufacturing and Applying,developed full series cylinder type diesel pile hammers.popular models :D19, D25,D30,D36,D46,D62,D80,D100,D128,D138..D180

D series cylinder type hammer pile driver for construction, has the advantages of strong, low Oil consumption, high impact efficiency, good economy driving and long service time. It is suitable for construction foundation piles, concrete piles, precast concrete pile, steel pipe pile, steel sheet pile type

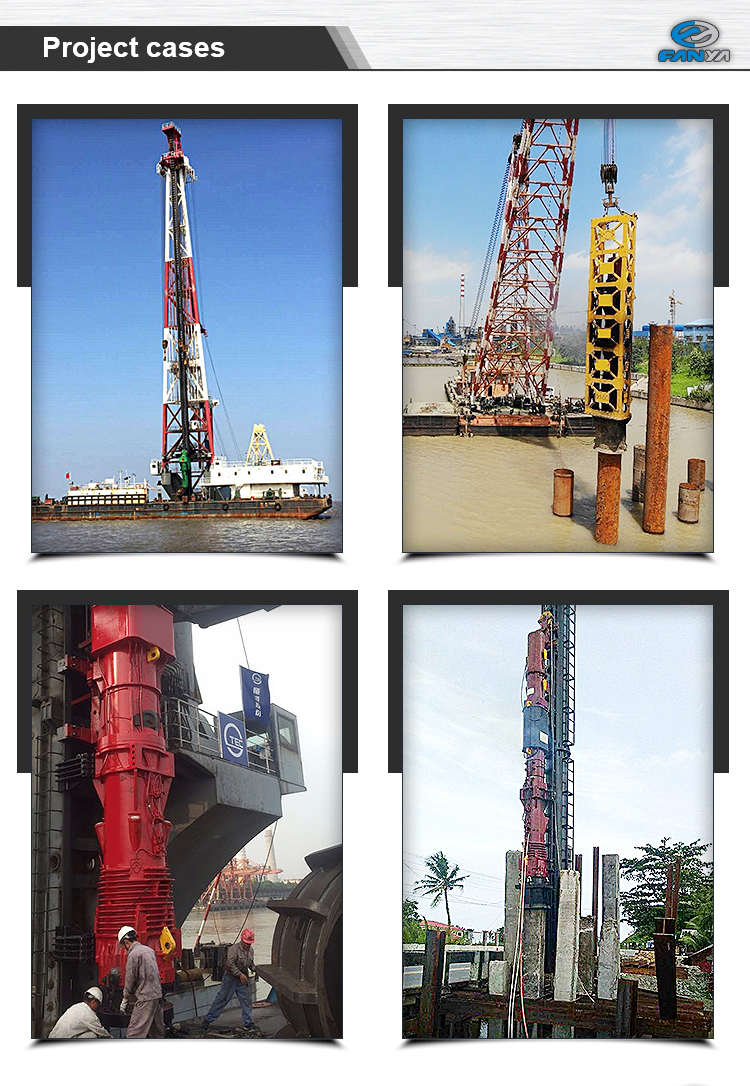

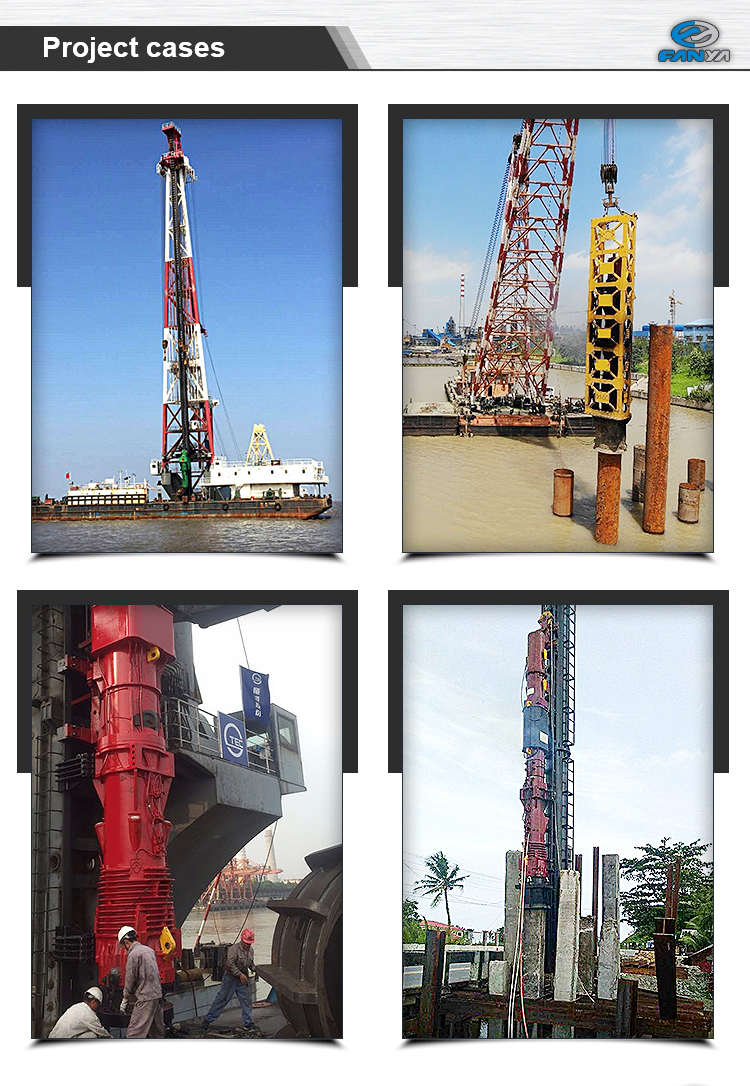

"FANYATOP" brand D series at the same time cylinder type concrete diesel pile hammer, not only has a good reputation in the domestic market, but also exported to Philippines, Indonesia, Thailand ,Russia, Myanmar, Vietnam, Spain Bangladesh,Southeast Asia, South Korea and the United States and other countries.

Model Technical data | Unit | D62 |

Batter piling forward and backward up to |

1:2/1:1 |

Impact Weight (piston) | kg | 6200 |

Energy per blow | Nm | 218960 ~107050 |

Number of blows | min-l | 36~50 |

Force of explosion pressure on pile max. | KN | 1800 |

Suitable for driving piles up to | Kg | 25000 |

Permissible rope dimmeter for deflector sheave of tripping device max. | mm | 38 |

Consumption | Diesel oil | L/h | 20 |

Lubricant | L/h | 3.2 |

Volume | Diesel oil tank | L | 98 |

Lube tank | L | 31.5 |

Weight | Diesel pile hammer approx. | kg | 12280 |

Tripping device approx | kg | 400 |

Transport bracket/cradle approx. | kg | 72 |

Transport guard approx. | kg | 34 |

Tool box approx | kg | 125 |

Dimension | Lenght of Diesel pile hammer (a/al) | mm | 6967 |

Outer diameter of impact block (b) | mm | 710 |

Overall dimensions measured over fastening screws of the guide jaws (c) | mm | 860 |

Width of Diesel pile hammer (d) | mm | 800 |

Width for connection of guide jaws (e) | mm | 560 |

Center of Diesel pile hammer up to pump guard (f) | mm | 490 |

Center of Diesel pile hammer up to center of threaded hole for fastening screw of the guide jaws (g) | mm | 380 |

Depth of Diesel pile hammer (h) | mm | 970 |

Standard distance from center of Diesel pile hammer up to the center of lead (H) | mm | 560 |

Leads width (L) | mm | 600x(Φ102) |

Packaging & Shipping

The standard set of tubular pile diesel hammer include:

- diesel pile hammer

- drive cap

- Accessories.

We packed with export standard steel carrier and ship by 20GP or 40GP container

Payment Term:

1. T/T,L/C at Sight,,or other payment terms according to actual situations.

2. Trade term: EXW, FOB, CNF, CIF all accepted.

Business Support

1. Suggest the best solution(suitable model) after study clients’ project and pile information(geological report,pile type,pile lenth,pile size,match with what machinery....)

2. Provide drawings for clients to confirm within three days after signing the contract for non-standard products, and produce according to the drawings(pile leader and pile cap)

3. Every diesel pile hammer will be tested well before shippment. Every single product has its own production code, certification of quality and operation Instruction

4. Timely parts service:enough parts stock

5. Our engineers can come to client jobsite for technical support .24 hours After-sale service hotline 0516-86225766