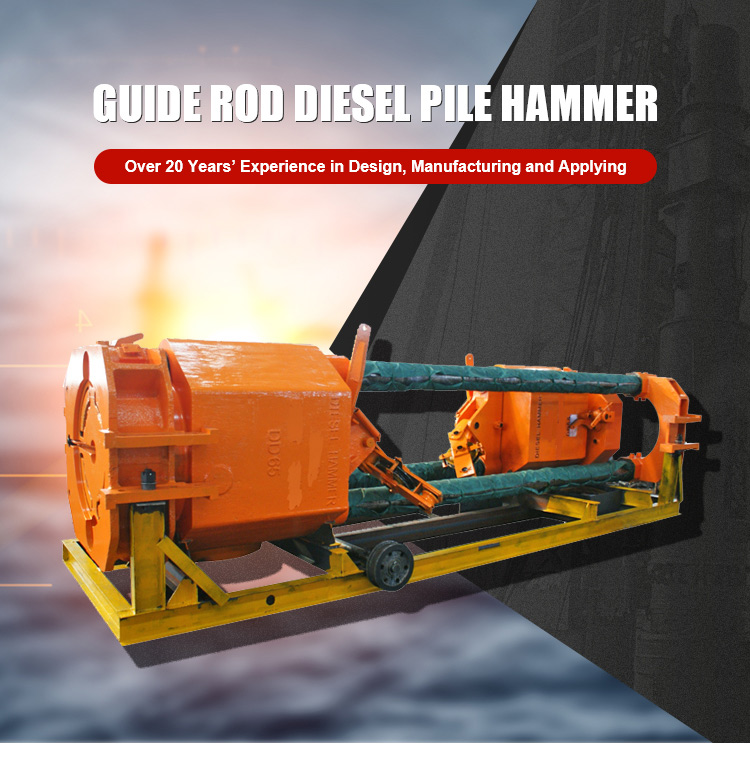

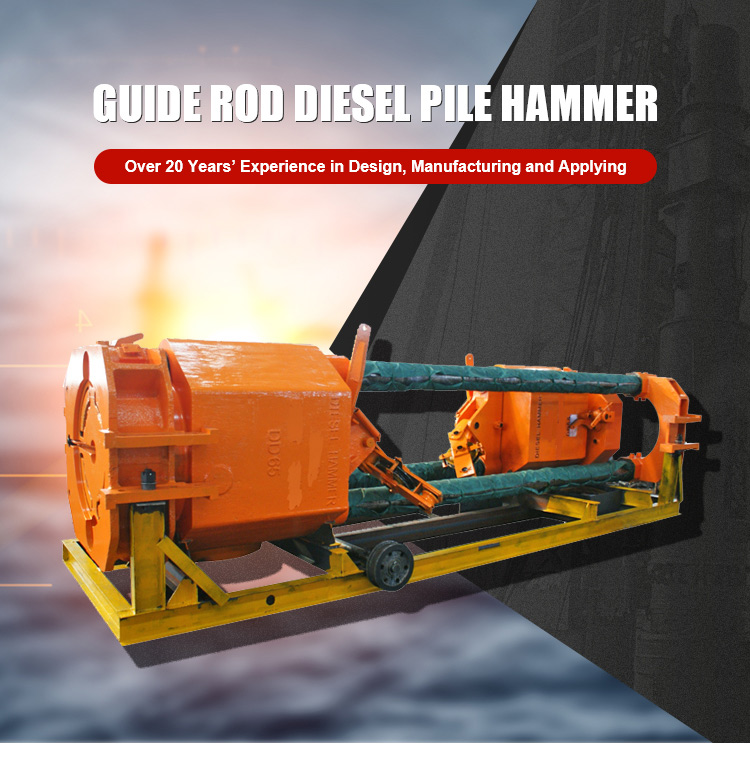

FANYATOP Brand DD series diesel pile hammers are over 20 Years’ Experience in Design, Manufacturing and Applying,developed full series guide rod diesel pile hammers.popular models :DD25 DD35 DD45 DD55,DD65,DD75 DD85..DD200.

FANYATOP Brand DD serie

1. The guide rod diesel hammer is pressed onto the pile cap with a plunger as the hammer seat, and lifted and lowered along two guide rods with a cylinder as the hammer head. When driving piles, first lift the pile into the pile frame gantry, then place the diesel hammer on the top of the pile, lower the hook to lift the cylinder, and release the hook to let the cylinder fall into the plunger, compressing the air enclosed in the cylinder. The cylinder continues to fall until the pressure pin outside the cylinder pushes the rocker arm of the fuel pump on the hammer seat. When the fuel pump sprays oil mist into the cylinder, it encounters high-temperature gas above the ignition point and immediately ignites. The explosive force impacts downwards, causing the pile to sink and push upwards, causing the cylinder to rise again. When the cylinder falls down along the guide rod again, the second impact cycle begins.

2. Its working principle is similar to that of a single cylinder two-stroke diesel engine, which uses the strong pressure generated by the combustion explosion of atomized diesel injected into the combustion chamber of the cylinder under high pressure and high temperature to drive the hammer to work

Diesel hammers use fuel explosions to propel pistons back and forth and hammer pile driving, with piston weights ranging from several hundred kilograms to several tons. When sinking a pile with a hammer, it is advisable to strike it lightly with a heavy hammer. If a heavy hammer hits heavily, most of the hammering energy is absorbed by the pile body, making it difficult to drive the pile in, and the pile head is easily broken. There should be a certain ratio between the weight of the hammer and the weight of the pile, or the hammering stress should be controlled to prevent the pile from being damaged. Pile frame is a pile driving equipment that supports the pile body and pile hammer, guides the direction of the pile during the sinking process, and enables the pile hammer to impact in the required direction

The work of a diesel hammer relies on compression ignition of diesel, so it is necessary to ensure that the enclosed gas in the cylinder reaches a certain compression ratio. Sometimes, when driving on soft soil layers, the reaction force is too small and the compression is not enough to ignite and detonate. Therefore, it is necessary to lift the hammer head multiple times with a hook to detach and impact before starting. The hammer seat of the diesel hammer is equipped with a fuel injection pump, fuel tank, cooling water tank, and pile cap. The clearance between the plunger and cylinder is sealed with an elastic plunger ring

3.Diesel hammer is a type of construction machinery commonly used in construction

Diesel hammers use fuel explosions to propel pistons back and forth and hammer pile driving, with piston weights ranging from several hundred kilograms to several tons.

When sinking a pile with a hammer, it is advisable to strike it lightly with a heavy hammer. If a heavy hammer hits heavily, most of the hammering energy is absorbed by the pile body, making it difficult to drive the pile in, and the pile head is easily broken. There should be a certain ratio between the weight of the hammer and the weight of the pile, or the hammering stress should be controlled to prevent the pile from being damaged.

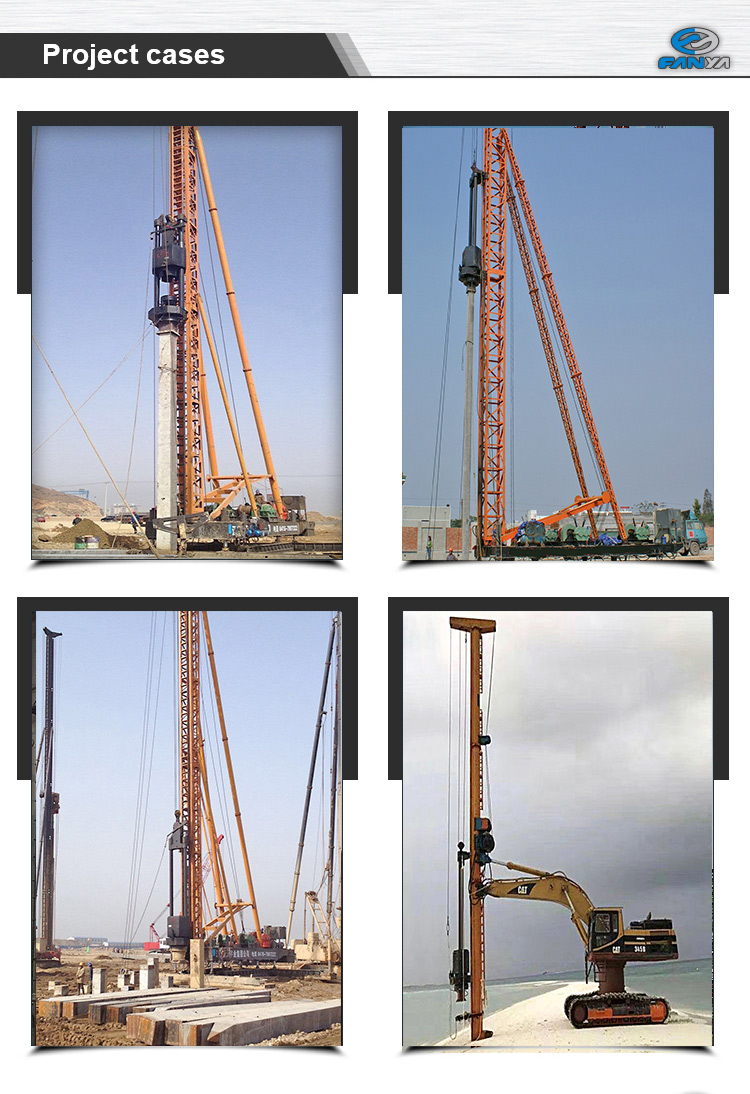

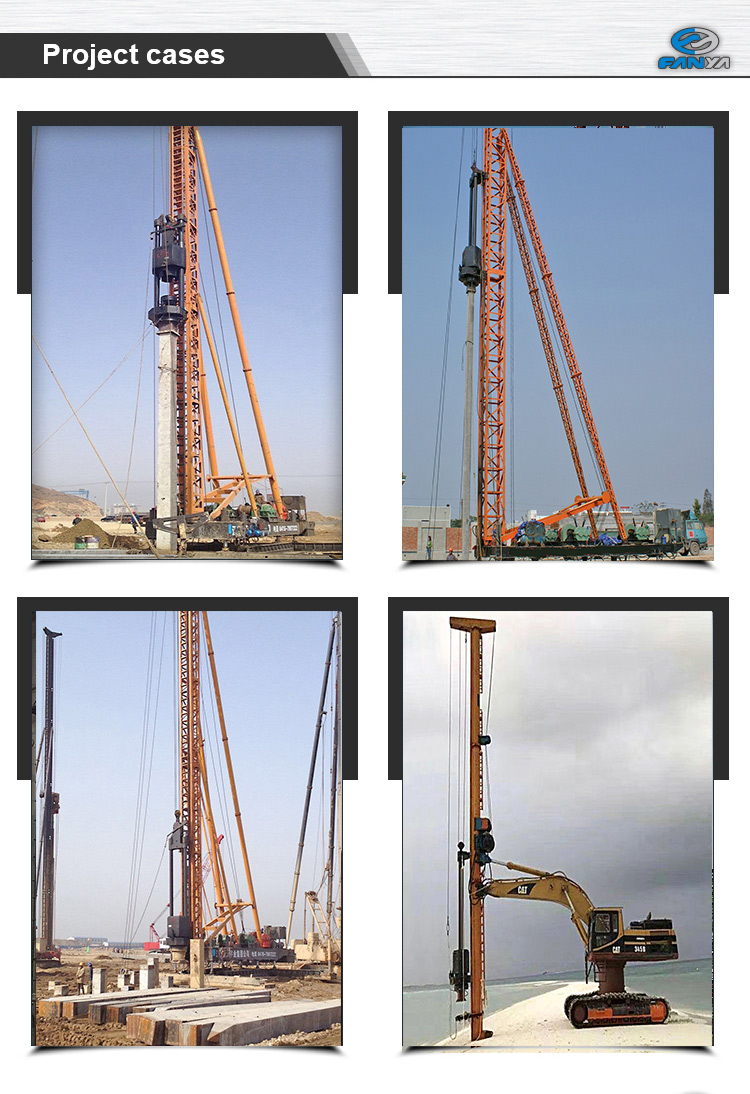

Pile frame is a pile driving equipment that supports the pile body and pile hammer, guides the direction of the pile during the sinking process, and enables the pile hammer to impact in the required direction

Type Designation | DD180 |

Cylindercomplex mass(Kg) | 18000 |

Max.cylinder stroke(m) | 3.0 |

Max.energy(Kj) | 540 |

Oil comsumption(I/h) | 48 |

Force of exploson pile(KN) | 4510 |

Suitable for driving piles(Kg) | 55000 |

Reduction ration | 30 |

Hammer mass(Kg) | 34800 |

Guike distance(mm) | 600 |

Packaging & Shipping

The Standard Set Of Pile HammerInclude:

- diesel pile hammer

- drive cap

- Accessories.

We packed with export standard steel carrier and ship by 20GP or 40GP container

Payment Term:

1. T/T,L/C at Sight,,or other payment terms according to actual situations.

2. Trade term: EXW, FOB, CNF, CIF all accepted.

Business Support And Service

1. Suggest the best solution(suitable model) after study clients’ project and pile information(geological report,pile type,pile lenth,pile size,match with what machinery....)

2. Provide drawings for customers to confirm within three days after signing the contract for non-standard products, and produce according to the drawings(pile leader and pile cap)

3. Every diesel pile hammer will be tested well before shippment. Every single product has its own Production Code, Certification of Quality and Operation Instruction

4. Timely parts service:enough parts stock

5. Our engineers can come to client jobsite for technical support .24 hours After-sale service hotline 0516-86225766