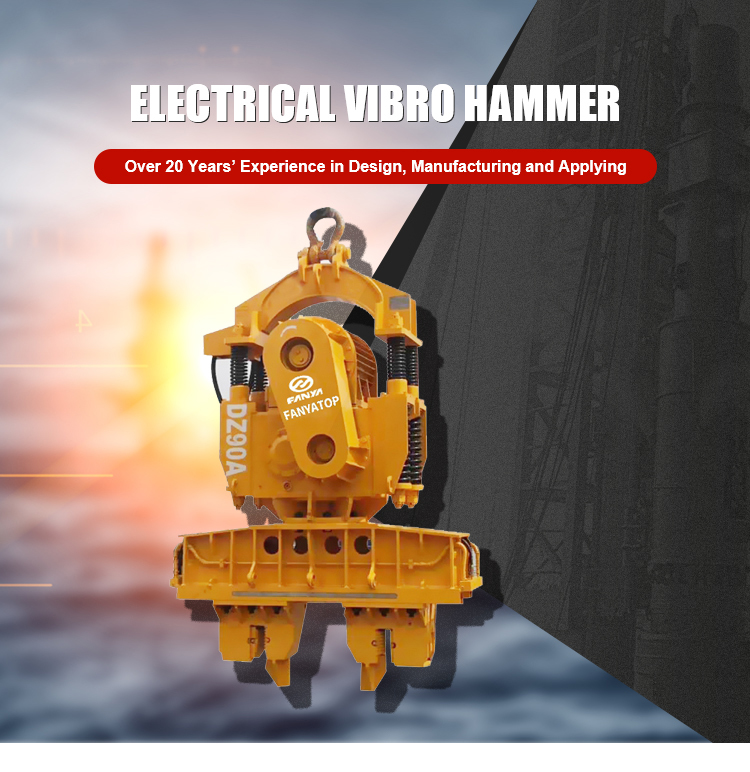

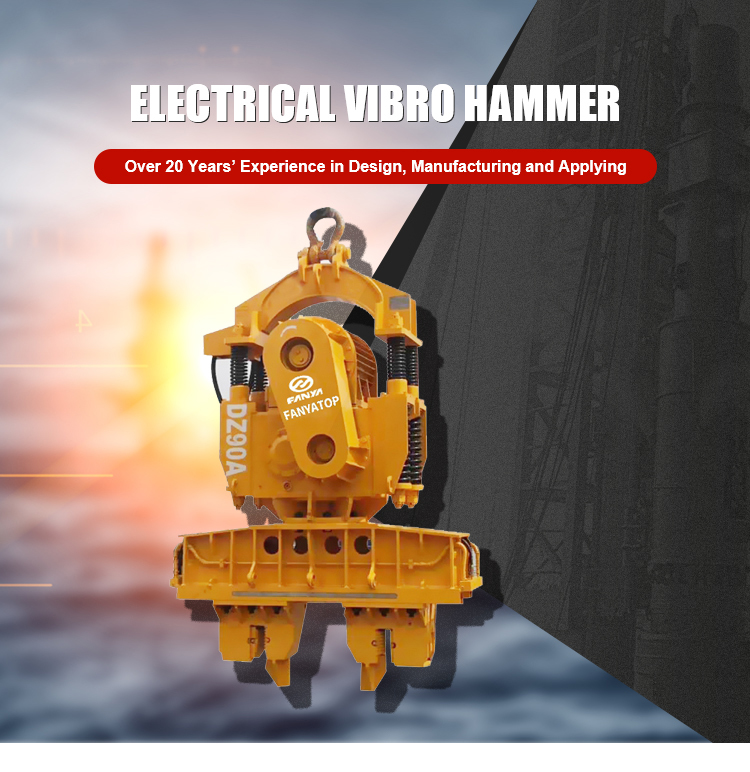

The models of FANTATOP brand electric vibratory hammer include DZ30A, DZ45A, DZ60A, DZ90A, DZ120A, DZ135A, DZ150A, DZ200A, mainly used for piling and pulling concrete piles, steel pipe piles, steel sheet piles, etc.

Vibration hammer daily maintenance and maintenance

1) Keep the vibrating hammer clean, and wipe off the oil, dust, rust and water on the hammer body and power station after each shift.

2) Every fastener should be checked frequently to keep the connection firm and reliable.

3) Each lubrication point should be lubricated according to the lubrication requirements.

4) The hydraulic oil in the oil tank should maintain a normal level and the oil temperature should remain normal. Always check the cleanliness of the oil and place it for contamination.

5) Always check whether water enters the hydraulic oil tank. If the water causes emulsification of the oil, remove the water or replace the hydraulic oil

6) Always check whether each instrument is stable and ready for normal operation, otherwise it should be repaired or replaced.

7) Check if there is any oil leakage in the oil system and deal with it in time.

8) Check whether the liquid level of the diesel tank, engine oil tank and cooling water tank is normal. If the liquid level is too low, please add it in time.

MODEL | DZ135A |

Motor Power | 135KW |

Frequency | 666r/min |

Eccentric moment | 1220Nm |

Centrifugal force | 604kN |

Amplitude | 18.6mm |

Max.Extraction Force | 400kN |

Overall Dimensions H | 3.1m |

Overall Dimensions L | 1.72m |

Overall Dimensions W | 1.4m |

Total Weight | 9100kg |

Wire cable | 75mm2 |

Clamp | Single/Double |

Diameter of the pile | Φ600-Φ2000mm |

Generator capacity | ≥450kW |

Min crane capacity | ≥70t |

Packaging & Shipping

The standard set of electric vibro hammers include:

- electric vibro hammers

- Clamps

- Accessories.

We packed with export standard package and ship by 20GP or 40GP container

Payment Term:

1. T/T,L/C at Sight,,or other payment terms according to actual situations.

2. Trade term: EXW, FOB, CNF, CIF all accepted.

Business Support

1. Suggest the best solution(suitable model) after study clients’ project and pile information(geological report,pile type,pile lenth,pile size,match with what machinery....)

2. Every hydraulic vibro hammer will be tested well before shippment and operation Instruction will send to clients by courier

3. Timely parts service:enough parts stock

4. Our engineers can come to client jobsite for technical support . 24 hours After-sale service hotline 0516-86225766