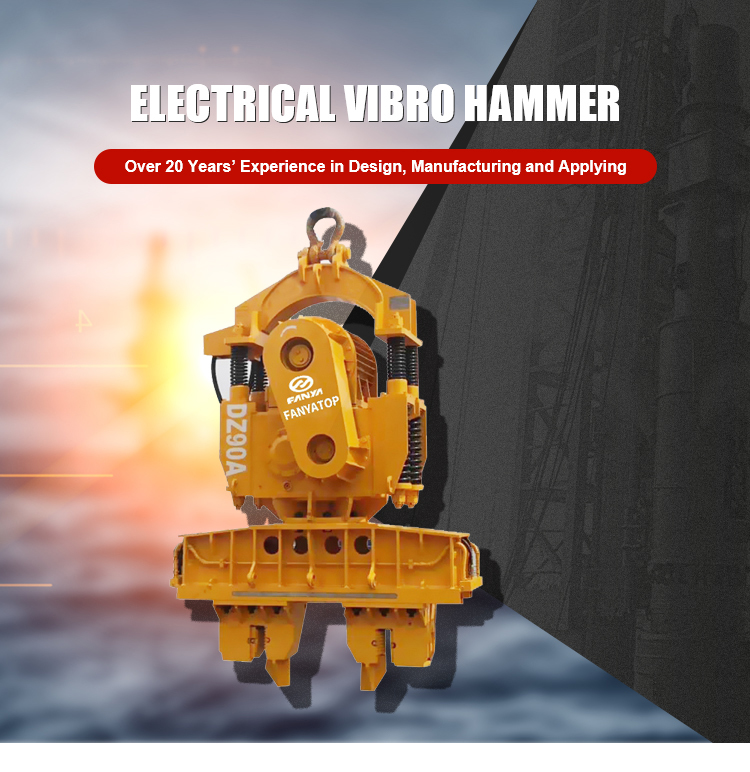

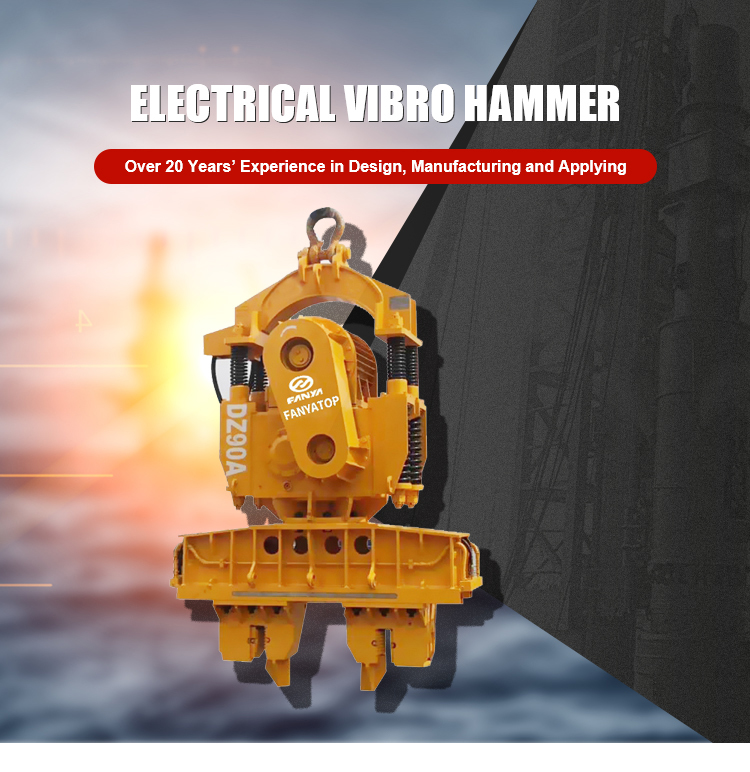

The models of FANTATOP brand electric vibratory hammer include DZ30A, DZ45A, DZ60A, DZ90A, DZ120A, DZ135A, DZ150A, DZ200A, mainly used for piling and pulling concrete piles, steel pipe piles, steel sheet piles, etc.

Its performance index has reached the international advanced level of similar products. It has the characteristics of strong pouring force, good quality of sinking pile, strong and durable, few failures, convenient use and maintenance, strong power adaptability, low noise, etc .; after matching with pile frame, it can sink concrete pouring pile, concrete bottom pile, lime pile, Sand piles and gravel piles; after being equipped with pile clamps, precast concrete piles and various steel piles can be drawn. Models are 40kw to 200kw and so on. They are ideal equipment for basic constructions such as highways, bridges, airports, and buildings.

What are the main characteristics of the electric vibration hammer?

The main characteristics of the electric vibration hammer during operation:

1. Both pile sinking and pile pulling are possible. Because the vibratory hammer achieves the goal of sinking the pile by reducing the frictional resistance between the pile and the raw soil, in a situation where the frictional resistance between the pile and the raw soil is reduced, a force slightly larger than the weight of the pile and the hammer Pile up. Because of this, the electric vibratory hammer is not only suitable for sinking piles, but also suitable for pulling piles.

2. The construction operation is more convenient. The electric vibratory hammer does not need to be provided with a guide pile frame during the construction, as long as it can be lifted by a crane to operate, but it requires sufficient power supply.

3. With environmental protection function. The electric hammer has low noise during operation, no harmful gas is generated, no damage to the pile head, fast operation speed, convenient operation, simple protection, and low construction cost.

MODEL | DZ150A |

Motor Power | 150kW |

Frequency | 940r/min |

Eccentric moment | 1000Nm |

Centrifugal force | 1000kN |

Amplitude | 12.5mm |

Max.Extraction Force | 400kN |

Overall Dimensions H | 3.3m |

Overall Dimensions L | 1.71m |

Overall Dimensions W | 1.5m |

Total Weight | 9535kg |

Wire cable | 95mm2 |

Clamp | Single/Double |

Diameter of the pile | Φ600-Φ2500mm |

Generator capacity | ≥450kW |

Min crane capacity | 80t |

Packaging & Shipping

The standard set of electric vibro hammers include:

- electric vibro hammers

- Clamps

- Accessories.

We packed with export standard package and ship by 20GP or 40GP container

Payment Term:

1. T/T,L/C at Sight,,or other payment terms according to actual situations.

2. Trade term: EXW, FOB, CNF, CIF all accepted.

Business Support

1. Suggest the best solution(suitable model) after study clients’ project and pile information(geological report,pile type,pile lenth,pile size,match with what machinery....)

2. Every hydraulic vibro hammer will be tested well before shippment and operation Instruction will send to clients by courier

3. Timely parts service:enough parts stock

4. Our engineers can come to client jobsite for technical support . 24 hours After-sale service hotline 0516-86225766