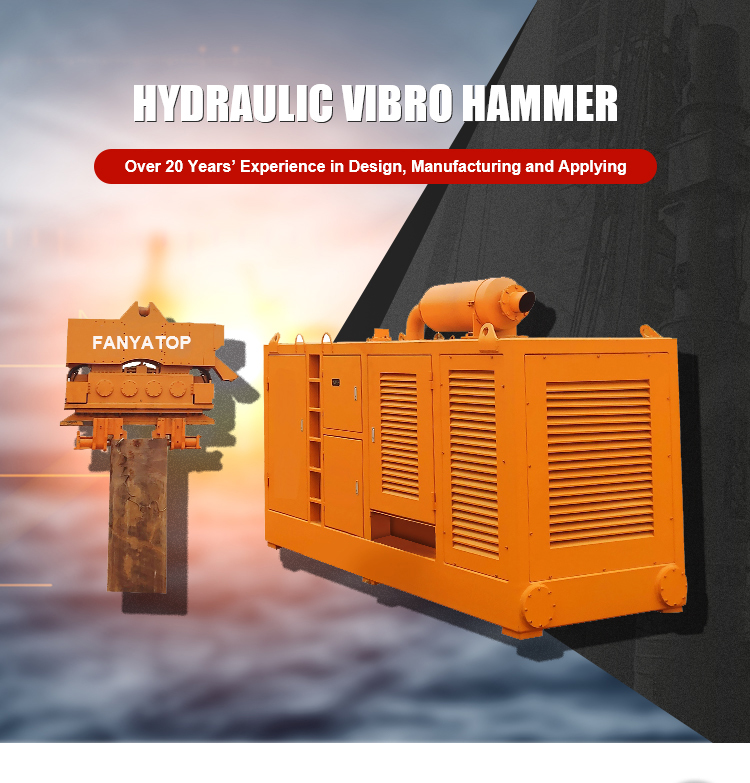

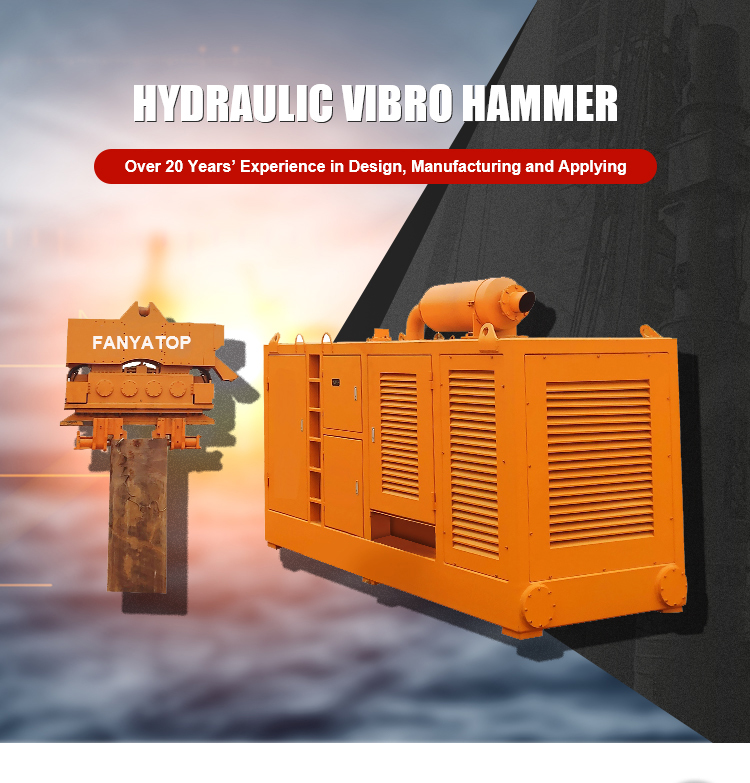

FANYATOP brand High Frequency Hydraulic vibratory hammers has been quickly adapted to high-speed railways, marine engineering, reclamation and bridge and wharf engineering, deep foundation pit support, and foundation treatment of ordinary buildings. The hydraulic sheet pile vibro hammer introduces foreign advanced technology, owns the proprietary intellectual property rights, and superior performance. It adopts a hydraulic power station as the hydraulic power source, and generates high-frequency vibration through the vibration box, so that the pile can easily penetrate into the soil layer. It is no pollution, high effiency,low noise and no damage to the pile.

Vibration sinking and pulling pile speed is generally 4-7 meters per minute, the fastest is 12 meters per minute (in non-muddy soil), the construction speed is much faster than other pile driving machinery, and the working efficiency is 40% -100% higher better than pneumatic hammer, diesel hammer and electric hammer.

In addition to not being able to enter the rock, the high-frequency hydraulic vibratory pile hammer is suitable for construction in any harsh geological conditions, and can easily penetrate the pebble layer, sand layer and other geology. It is suitable for driving piles of any shape and any material, such as steel pipe piles and concrete pipe piles; the diameter of the pipe pile is from 5 cm to 1340 cm.

The high-frequency hydraulic vibration pile driving body is fully enclosed compared with the electric hammer, and can be operated underwater. The structure is simple, and the maintenance workload is small. The small size and light weight can provide powerful performance. Under similar performance, the weight of the high frequency hydraulic vibration hammer of the same level is only less than half of that of the electric hammer. Safe operation and avoid the danger of high voltage electricity. According to the needs of soil quality, it can do stepless vibration frequency adjustment. High-frequency vibration greatly reduces soil resistance, making pile driving and pulling more smooth.

When making concrete pouring piles, the same set of steel casings can be reused, saving costs.

The high-frequency hydraulic sheet pile vibratory hammer can also use a rotary drilling drill to provide hydraulic power source. The high-frequency hydraulic vibrating pile hammer can be lifted by the main winding of the rotary drilling drill to complete the pulling operation of various piles

Vibro Hammer |

Model |

| FYV80 | FYV100 | FYV120 | FYV180 | FYV260 | FYV320 |

Frenquency | r/min | 1700 | 1700 | 1850 | 1680 | 1450 | 1700 |

Vibro Force | kN | 800 | 1000 | 1200 | 1800 | 2600 | 3200 |

Max Pile-pull Force | kN | 543 | 776 | 840 | 1260 | 1800 | 2240 |

Overall Weight | Kg | 5200 | 5600 | 5900 | 7000 | 8900 | 9200 |

Overall Size LxWxH | mm | 2995x535x2385 | 2995x535x2385 | 2995x535x2385 | 3030x560x2550 | 3230x580x2650 | 3230x580x2650 |

Power Pack |

Model |

| HP360 | HP360 | HP360 | HP600 | HP800 | HP1200 |

Engine | TYPE | NTA855-P360 | NTA855-P360 | NTA855-P360 | KTTA19-C700 | KTTA19-C700 | KTTA38-P1050 |

Power | KW/HP | 269/360 | 269/360 | 269/360 | 522/700 | 522/700 | 772/1050 |

Speed | rpm | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 |

Max Presusure | Mpa | 350 | 350 | 350 | 350 | 350 | 350 |

Max Flow | L/min | 400 | 400 | 400 | 540 | 756 | 1020 |

Overall Weight | kg | 5500 | 5500 | 5500 | 9200 | 9200 | 12500 |

Packaging & Shipping

The standard set of hydraulic vibro hamme include:

- Hydraulic vibro hammer

- Clamps

- Accessories.

We packed with export standard package and ship by 20GP or 40GP container

Payment Term:

1. T/T,L/C at Sight,,or other payment terms according to actual situations.

2. Trade term: EXW, FOB, CNF, CIF all accepted.

Business Support

1. Suggest the best solution(suitable model) after study clients’ project and pile information(geological report,pile type,pile lenth,pile size,match with what machinery....)

2. Every hydraulic vibro hammer will be tested well before shippment and operation Instruction will send to clients by courier

3. Timely parts service:enough parts stock

4. Our engineers can come to client jobsite for technical support . 24 hours After-sale service hotline 0516-86225766