Summary:

Understanding how a diesel pile hammer works is crucial for construction and engineering projects that require deep foundations. Diesel pile hammers, also known as diesel pile drivers, are used extensively in foundation work to drive piles into the ground efficiently. This article will explore the working mechanism of diesel pile drivers, their benefits, and their role in the construction industry. Additionally, we will discuss the various types and functions of diesel hammers to help you understand their importance and why you should choose FANYATOP for your pile-driving needs.

The Mechanics of a Diesel Pile Hammer

Diesel pile hammers operate using the principles of compression and combustion, similar to a diesel engine. The working cycle starts when the hammer's piston is lifted to a certain height and released, which causes it to fall due to gravity. Upon hitting the anvil at the base of the hammer, a compression chamber is formed, igniting the diesel fuel. This controlled explosion forces the piston back upward, initiating the next cycle. This repetitive action drives the pile into the ground with significant force.

When considering how does a diesel pile driver work, it's important to understand the energy efficiency it provides. The combustion process continuously powers the system, making diesel hammers one of the most self-sufficient tools in construction.

Types of Diesel Pile Hammers

Diesel pile drivers come in two primary types: single-acting and double-acting. In a single-acting diesel hammer, the upward movement of the ram (or piston) is achieved solely by the combustion of the fuel. This type of hammer is particularly suited for smaller or medium-sized piles. In contrast, the double-acting diesel hammer uses both combustion and hydraulic force to lift the ram, providing additional power for driving larger piles.

Knowing the difference between these types helps contractors select the best tool for the job. Understanding diesel pile driver how it works ensures that the right equipment is chosen for each specific task, optimizing performance and reducing operational costs.

Benefits of Using Diesel Pile Hammers

Diesel pile hammers are known for their efficiency and cost-effectiveness. One of the primary advantages of diesel hammers is their ability to operate independently without the need for external energy sources. Since the hammer's cycle is powered by the internal combustion of diesel fuel, it can perform continuously in challenging environments, which significantly reduces downtime.

Another benefit is the durability of diesel pile drivers. These machines are designed to withstand extreme conditions, such as those found in marine or deep foundation projects. This makes them a popular choice for contractors who need reliable and robust equipment. When evaluating how does a diesel hammer work, it becomes clear that their minimal maintenance needs and long-term operational efficiency make them a preferred tool in the industry.

Applications of Diesel Pile Drivers

Diesel pile drivers are widely used in various construction projects, including bridge foundations, high-rise buildings, ports, and offshore structures. Their ability to drive piles deep into the ground ensures that structures are anchored securely, which is vital for stability, especially in areas prone to seismic activity or heavy loads.

Understanding how does a diesel pile driver work helps construction teams assess whether this technology is suitable for their specific project. The speed and force provided by diesel hammers make them indispensable in large-scale projects requiring deep foundation work.

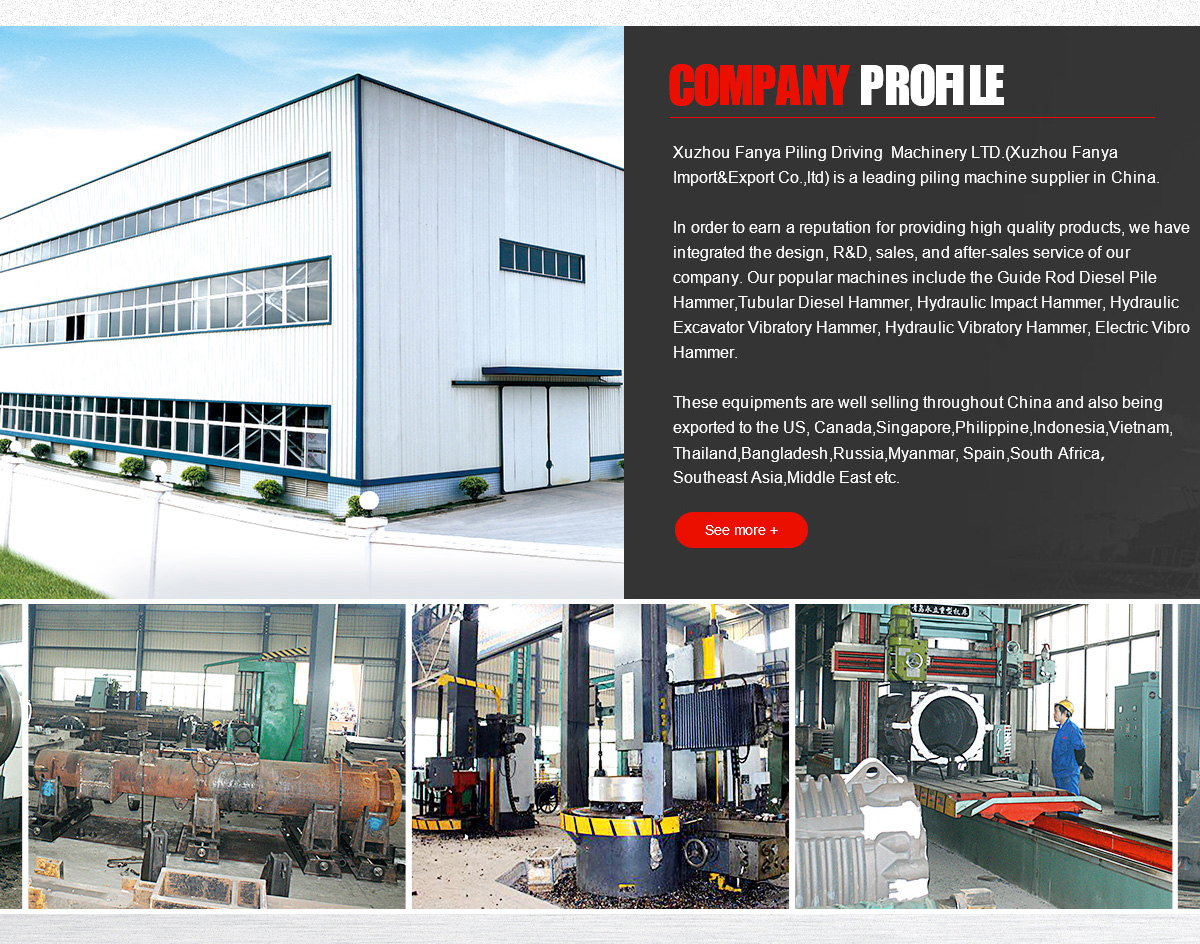

Why Choose FANYATOP for Your Diesel Pile Hammer Needs?

FANYATOP offers high-quality diesel pile hammers designed to meet the rigorous demands of modern construction. Our equipment is engineered for durability, efficiency, and cost-effectiveness, making us a trusted partner for construction firms worldwide. Whether you need a single-acting or double-acting diesel hammer, FANYATOP has the perfect solution for your project.

Conclusion

Diesel pile hammers are essential for driving piles into the ground quickly and efficiently, and understanding their mechanism helps contractors choose the right tools for their projects. The self-sustaining nature of diesel pile drivers, coupled with their robustness and low maintenance requirements, makes them an ideal choice for various construction applications. FANYATOP provides industry-leading diesel hammers designed to meet the challenges of modern construction, ensuring that your foundation work is completed on time and within budget.

FAQs:

1. How does a diesel pile driver work?

A diesel pile driver works by using the energy from diesel fuel combustion to drive piles into the ground. The piston is lifted and falls, compressing fuel and air, which ignites and generates force for pile driving.

2. What are the types of diesel pile hammers?

There are two main types: single-acting and double-acting diesel hammers. Single-acting hammers rely solely on combustion, while double-acting hammers use both combustion and hydraulic power.

3. Why are diesel pile hammers efficient?

Diesel pile hammers are efficient because they operate independently without needing external power sources. Their combustion cycle allows continuous operation, reducing downtime.

4. Where are diesel pile hammers used?

Diesel pile hammers are used in construction projects like bridge foundations, offshore structures, and high-rise buildings, where deep foundations are required.

5. Why choose FANYATOP for diesel pile hammers?

FANYATOP offers durable and efficient diesel pile hammers that are designed to meet the specific needs of your construction project, ensuring optimal performance and reliability.