Excavator vibratory hammers, often referred to as excavator pile hammers, are indispensable tools in modern construction. These attachments transform excavators into versatile machines capable of driving piles and sheet piles into the ground through vibration rather than impact. This guide delves into the world of excavator vibratory hammers, discussing their types, applications, advantages, disadvantages, and safety considerations.、

Overview of Excavator Vibratory Hammers

An excavator vibratory hammer is a specialized attachment mounted on the arm of an excavator. It comprises a hydraulic motor, eccentric weights, and a clamping mechanism. When activated, the eccentric weights generate high-frequency vibrations transmitted to the pile, facilitating its penetration into the ground. This method is often preferred over traditional impact hammers due to its reduced noise and vibration levels.

Types of Excavator Vibratory Hammers

Excavator vibratory hammers are categorized based on size, power, and specific applications. The primary types include:

Standard vibratory hammers: Versatile for various pile types and soil conditions.

Heavy-duty vibratory hammers: Designed for larger, heavier piles in challenging terrains.

Hydraulic vibratory hammers: Utilizing hydraulic power for enhanced efficiency and control.

The optimal type depends on project-specific requirements, pile dimensions, and soil conditions.

Applications of Excavator Vibratory Hammers

Excavator vibratory hammers are employed in diverse construction applications:

Pile driving: Installing piles for foundations, retaining walls, and bridge supports.

Sheet pile installation: Driving sheet piles for watertight barriers and temporary cofferdams.

Soil compaction: Improving soil stability and bearing capacity through vibration.

Pile extraction: Removing piles from the ground.

The versatility of excavator vibratory hammers makes them invaluable tools in the construction industry.

Advantages and Disadvantages of Excavator Vibratory Hammers

Excavator vibratory hammers offer several advantages:

Reduced noise and vibration: More environmentally friendly and less disruptive.

Higher productivity: Faster pile installation compared to impact hammers.

Versatility: Suitable for a wide range of pile types and soil conditions.

Reduced pile damage: Lower risk of pile breakage.

However, limitations include:

Limited penetration in dense soils: May require pre-boring in challenging conditions.

Higher equipment cost: Generally more expensive than impact hammers.

Careful consideration of these factors is crucial when selecting an excavator vibratory hammer.

Safety Precautions for Excavator Vibratory Hammers

Safe operation of excavator vibratory hammers is paramount. Essential safety measures include:

Operator training: Ensure operators are well-versed in equipment operation.

Regular inspections: Conduct thorough inspections before each use.

Personal protective equipment: Require operators to wear appropriate safety gear.

Safe work area: Establish a clear and safe working environment.

Emergency procedures: Develop and implement emergency plans.

Adherence to safety guidelines is essential to prevent accidents and injuries.

Conclusion

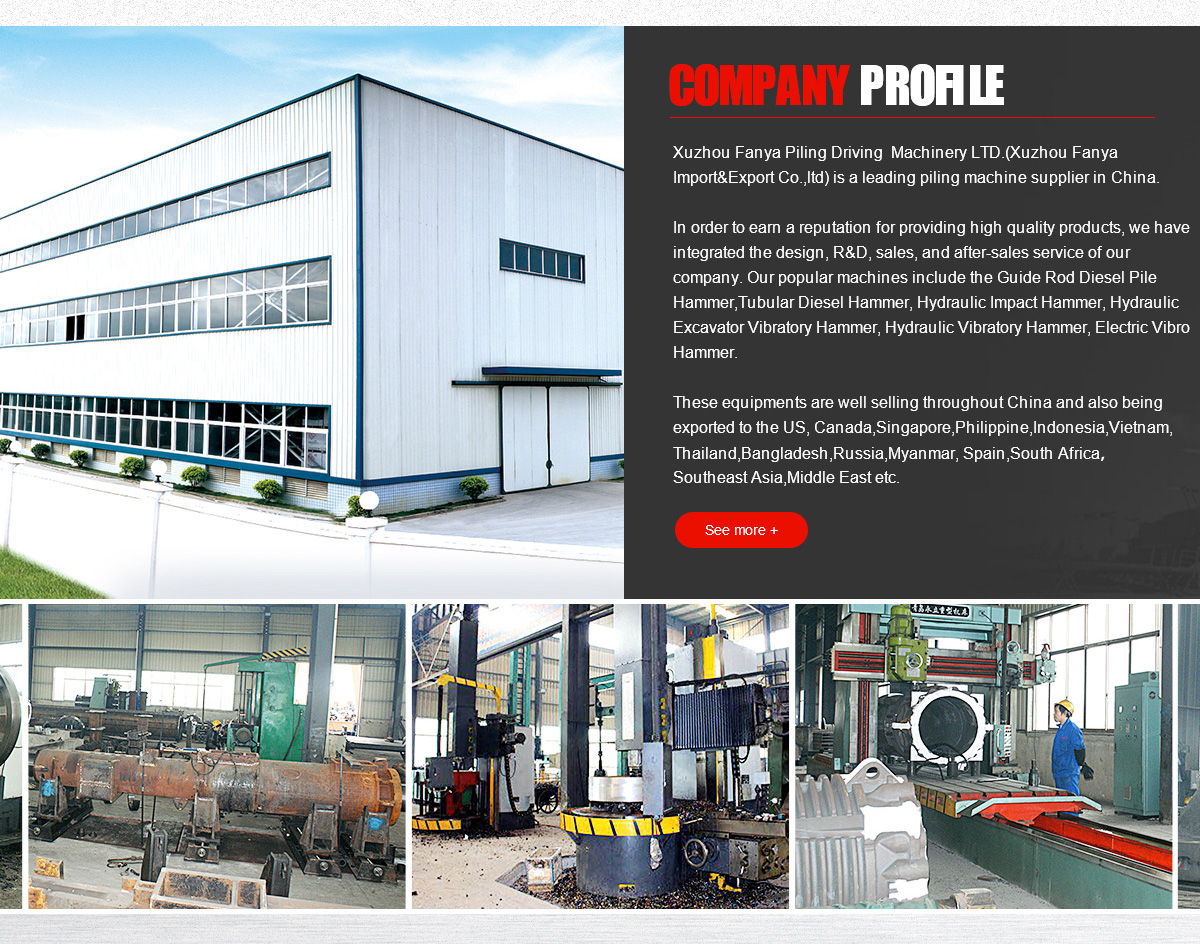

Excavator vibratory hammers, or excavator pile hammers, are powerful tools with numerous applications in construction. By understanding their types, advantages, and safety considerations, you can effectively utilize them to enhance project efficiency and productivity. When seeking high-quality excavator vibro hammers, consider partnering with a reputable excavator vibro hammer Factory or Manufacturer like FANYATOP.