A hydraulic vibratory hammer, also known as a hydraulic vibro hammer, is a specialized construction equipment used to drive piles into the ground through high-frequency vibrations. Unlike traditional impact hammers, which rely on forceful blows, hydraulic vibratory hammers generate powerful oscillatory movements that efficiently penetrate various soil conditions. This technology is particularly effective for hydraulic vibro hammer sheet pile driving due to its precision and speed.

How Does a Hydraulic Vibratory Hammer Work?

A hydraulic vibratory hammer comprises a hydraulic power unit, a vibrator, and clamps. The hydraulic system generates the energy to operate the vibrator, which produces high-frequency vibrations transmitted to the pile. These vibrations break down soil resistance, allowing the pile to penetrate deeper with minimal disturbance to the surrounding area.

Advantages of Hydraulic Vibratory Hammers

Efficiency: Compared to traditional methods, hydraulic vibratory hammers significantly increase pile driving speed and reduce operational costs.

Reduced Noise and Vibration: The technology minimizes noise and ground vibrations, making it suitable for urban and environmentally sensitive areas.

Versatility: Hydraulic vibratory hammers can be used in diverse soil conditions, from soft clays to dense sands.

Environmental Friendliness: By reducing noise and vibration, these hammers have a smaller environmental impact.

Applications of Hydraulic Vibratory Hammers

Hydraulic vibratory hammers find extensive applications in the construction industry, including:

Sheet Pile Driving: Installing interlocking sheet piles for retaining walls, cofferdams, and waterfront structures.

Foundation Construction: Driving piles for building foundations in various soil conditions.

Bridge Construction: Installing piles for bridge piers and abutments.

Wharf Construction: Driving piles for wharves, jetties, and marine structures.

Soil Improvement: Compacting soil for ground stabilization.

Choosing the Right Hydraulic Vibratory Hammer

Selecting the appropriate hydraulic vibratory hammer depends on several factors:

Pile Size and Material: Consider the dimensions and type of pile to be driven.

Soil Conditions: The hammer's vibration frequency and amplitude should match the soil type.

Project Requirements: Evaluate factors like noise restrictions, working space, and budget.

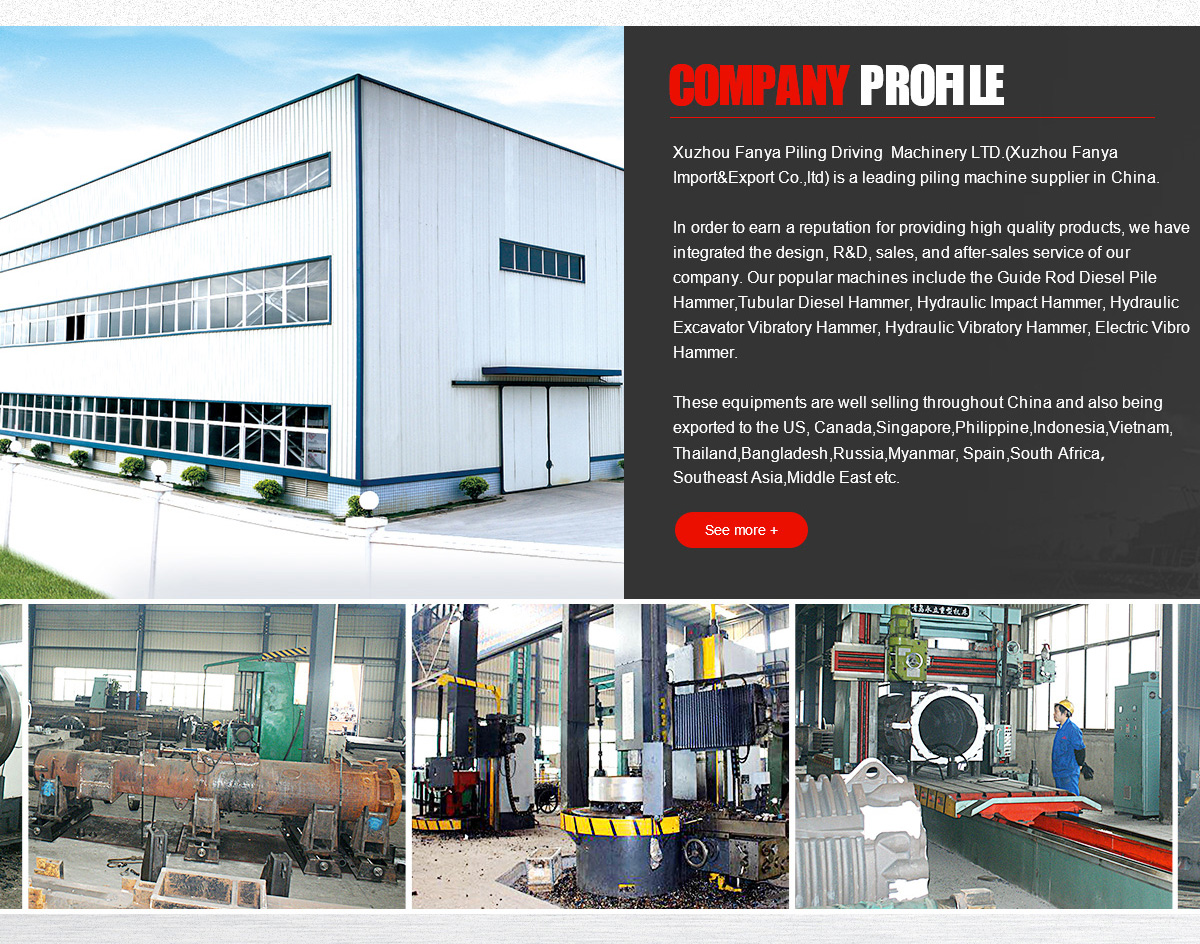

FANYATOP as a leading hydraulic vibratory hammer Manufacturer and Factory offers a comprehensive range of high-performance products to meet diverse project needs. Our commitment to quality and innovation ensures optimal efficiency and reliability.

Conclusion

Hydraulic vibratory hammers have revolutionized the construction industry by providing a more efficient, quieter, and environmentally friendly solution for pile driving. Their versatility and effectiveness make them indispensable for various projects.

FANYATOP is dedicated to delivering top-tier hydraulic vibratory hammers that exceed industry standards. Contact us today to discuss your project requirements and explore how our products can enhance your construction operations.